-

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogIn recent years, Haigelis has designed, manufactured, and installed a series of warehousing and logistics projects for well-known domestic companies such as Sinopec, PetroChina, Coca-Cola, Yihai Kerry, Alibaba Cainiao Logistics, Junlebao, Jinmailang, North China Pharmaceutical, Lucky Film, YTO Express, and Inner Mongolia Xinhua Publishing and Distribution Group.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

The "Past and Present Lives" of the Four way Shuttle Bus

Classification:

News

Release time:

2024-09-21

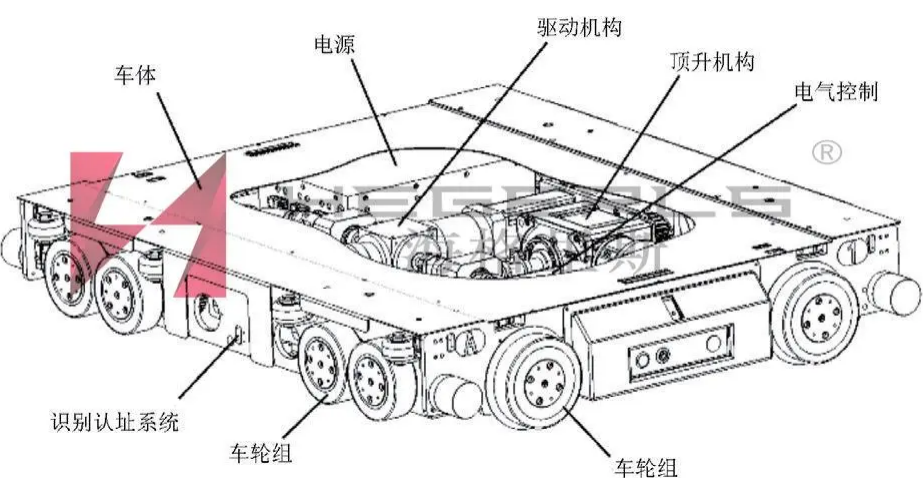

The four-way shuttle is a highly automated logistics equipment, and its development history and characteristics reflect an important step in the progress of logistics technology. The four-way shuttle can move in both the x-axis and y-axis of the shelf, and has the characteristic of being able to travel in all four directions without turning, which is also the origin of its name. The design of this device allows it to flexibly shuttle through narrow passages, maximizing the use of storage space, while also having features that improve work safety, such as equipped with collision avoidance systems and automatic parking functions. The emergence of four-way shuttle buses has greatly improved the storage efficiency and operational accuracy of warehouses, adopting advanced navigation technology and power systems, with significant advantages such as high space utilization, high efficiency and flexibility, improved safety, automation and intelligence.

The development of four-way shuttle vehicles has gone through several stages. From the perspective of product types, they are mainly divided into two categories based on their load capacity: pallet type (heavy-duty) four-way shuttle vehicles and box type (light-duty) four-way shuttle vehicles.

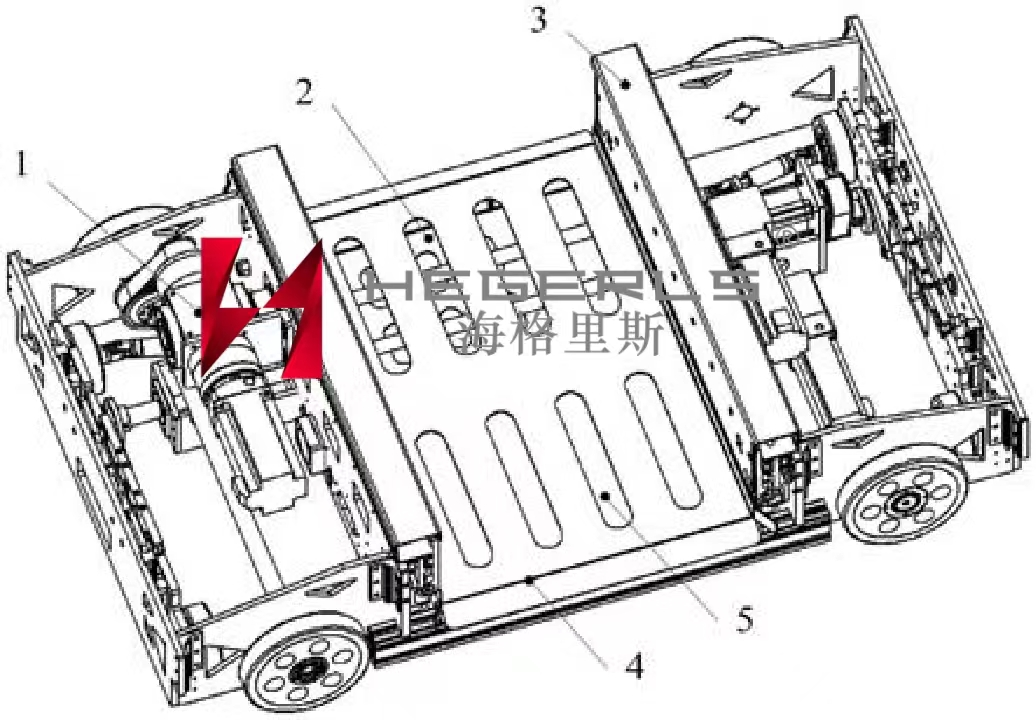

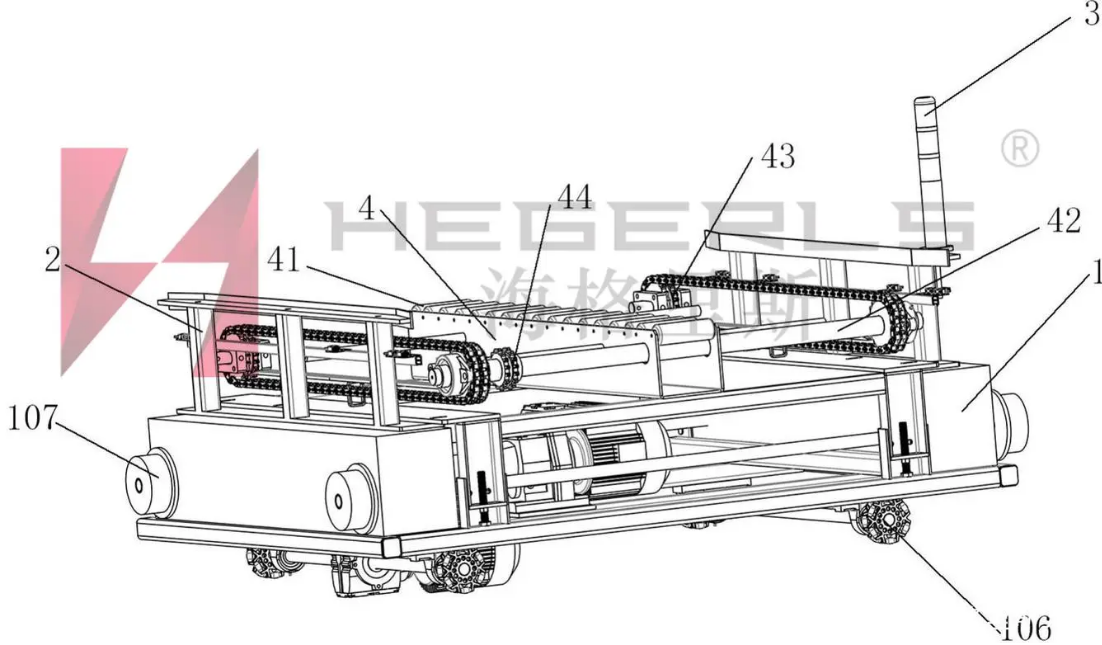

Box type shuttle cars are mainly used in high-speed picking scenarios and are suitable for industries with multiple specifications and storage, such as e-commerce, food, medicine, etc. Their key technologies are divided into three parts: hardware technology, software technology, and communication technology. Hardware technology mainly focuses on intelligent forklift technology, motion control technology, positioning control technology, power management technology, and other aspects. Software technology mainly includes dynamic optimization management of cargo locations and temporary storage spaces, task allocation and scheduling, and optimization of bus routes. Communication technology is mainly a technology for fast and frequent switching of base stations in a stable signal coverage, high traffic low latency, and large-area high-density continental shelf environment. In addition, related technologies such as rapid elevators, shelves, tracks, and conveyors, system stability, maintainability, and adaptability to the environment are key technologies that affect the performance of the entire shelf system.

The tray type (heavy-duty) four-way shuttle car is mainly used for the handling and transportation of tray goods, and can be combined with the upper computer or WMS system for communication to achieve automatic identification of goods and other functions. It mainly includes a two-way tray shuttle car system, a mother child shuttle car system, and a two-way shuttle car+stacker system. Among them, the two-way pallet shuttle was gradually accepted into the Chinese market in 2009. Due to the fact that the two-way shuttle can only use the "first in, first out" or "first in, first out" mode when loading and unloading goods, its early application was limited to large quantities and a small variety of goods. However, with the development of the market, the demand for small batch and multi frequency storage of goods is increasing day by day. At the same time, due to factors such as rising land costs, users are increasingly concerned about space saving and intensive storage. In this context, a four-way shuttle truck for pallets that integrates secure storage, space saving, and flexible scheduling has emerged.

The advantage of the four-way shuttle is not only reflected in its technical characteristics, but also in its improvement of warehouse operation efficiency. It can operate efficiently in a small space, reducing the need for manual intervention, lowering labor costs and operational risks. With the increasing demand for efficiency and flexibility in the logistics industry, four-way shuttle buses as a new type of logistics equipment have gradually attracted attention and been promoted and applied in multiple industries. Although four-way shuttle buses have many advantages and some challenges in practical applications, such as high costs, this does not hinder their enormous potential in improving warehousing and logistics efficiency.

In summary, the development history and technological characteristics of four-way shuttle cars demonstrate the trend of intelligent and automated logistics equipment. Their efficient utilization of warehouse space, improvement of operational efficiency, and guarantee of safety make four-way shuttle cars an indispensable part of modern logistics systems.

Key words:

Latest News

Advantages of Pallet Shuttle System

2021-04-22

Advantages of automated warehouse

2021-04-08

TEL: +86-13091097380

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China8

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2020 hebei walker metal products co., ltd

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home