-

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogIn recent years, Haigelis has designed, manufactured, and installed a series of warehousing and logistics projects for well-known domestic companies such as Sinopec, PetroChina, Coca-Cola, Yihai Kerry, Alibaba Cainiao Logistics, Junlebao, Jinmailang, North China Pharmaceutical, Lucky Film, YTO Express, and Inner Mongolia Xinhua Publishing and Distribution Group.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

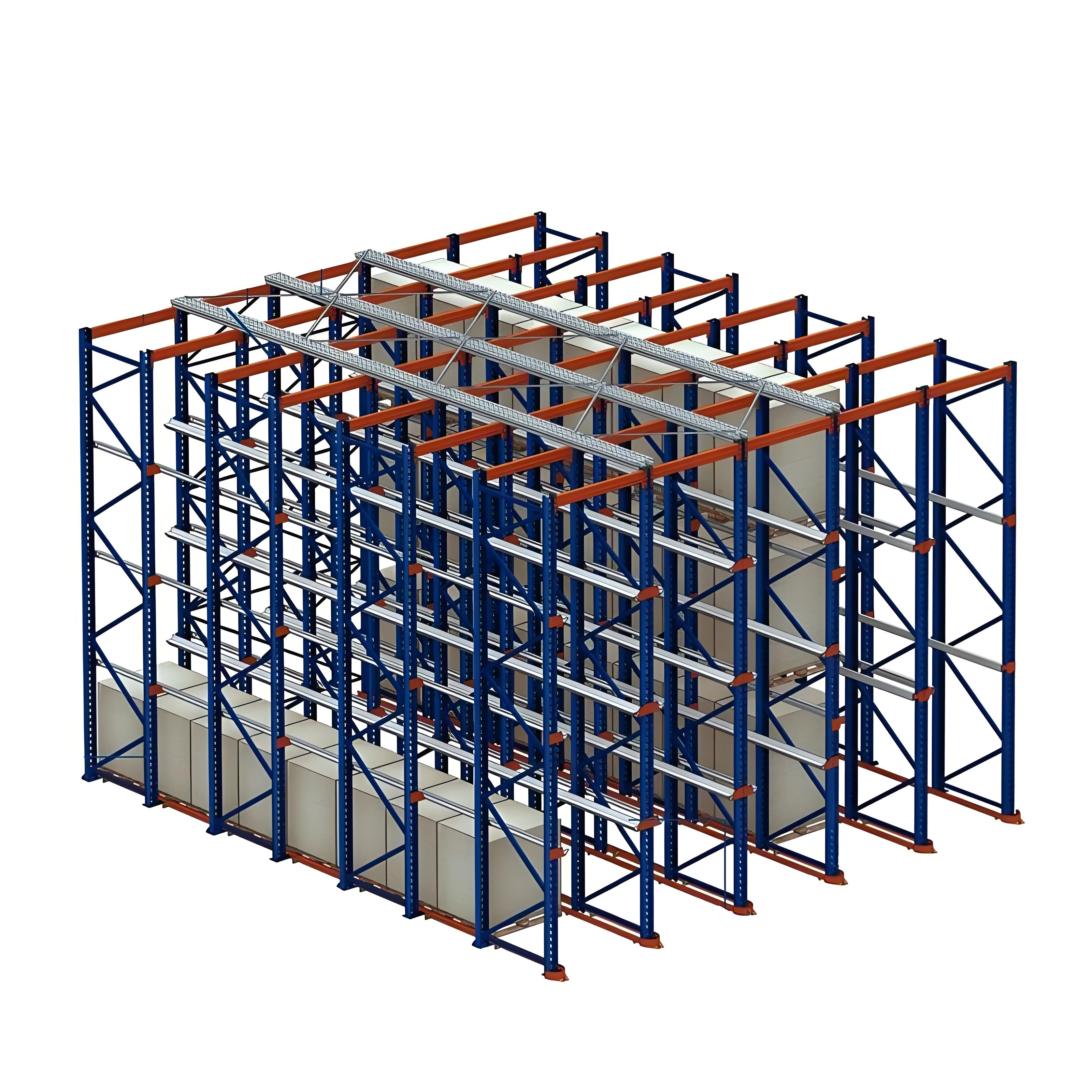

Shuttle racking

Classification:

Application:

Detailed introduction

Production Introduction

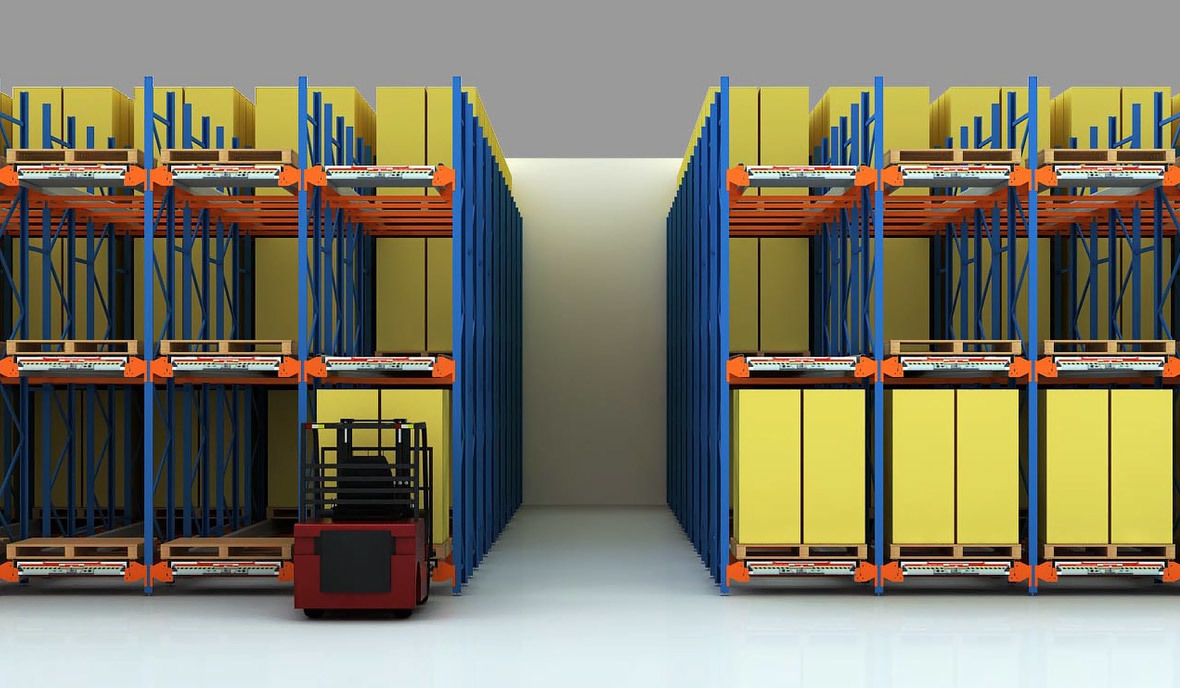

★ Shuttle shelving is an an upgraded and supplementary system for traditional high-density storage racks.

★ It combines features of multiple shelving types, integrating traditional dense storage with automated control capabilities.

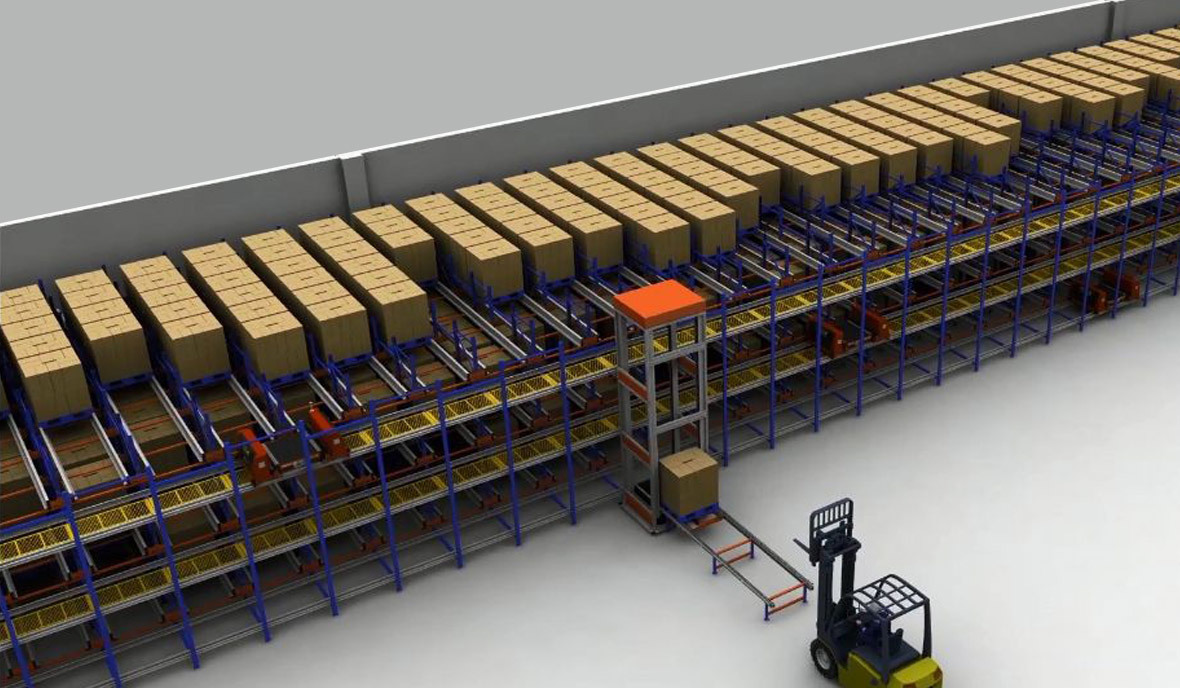

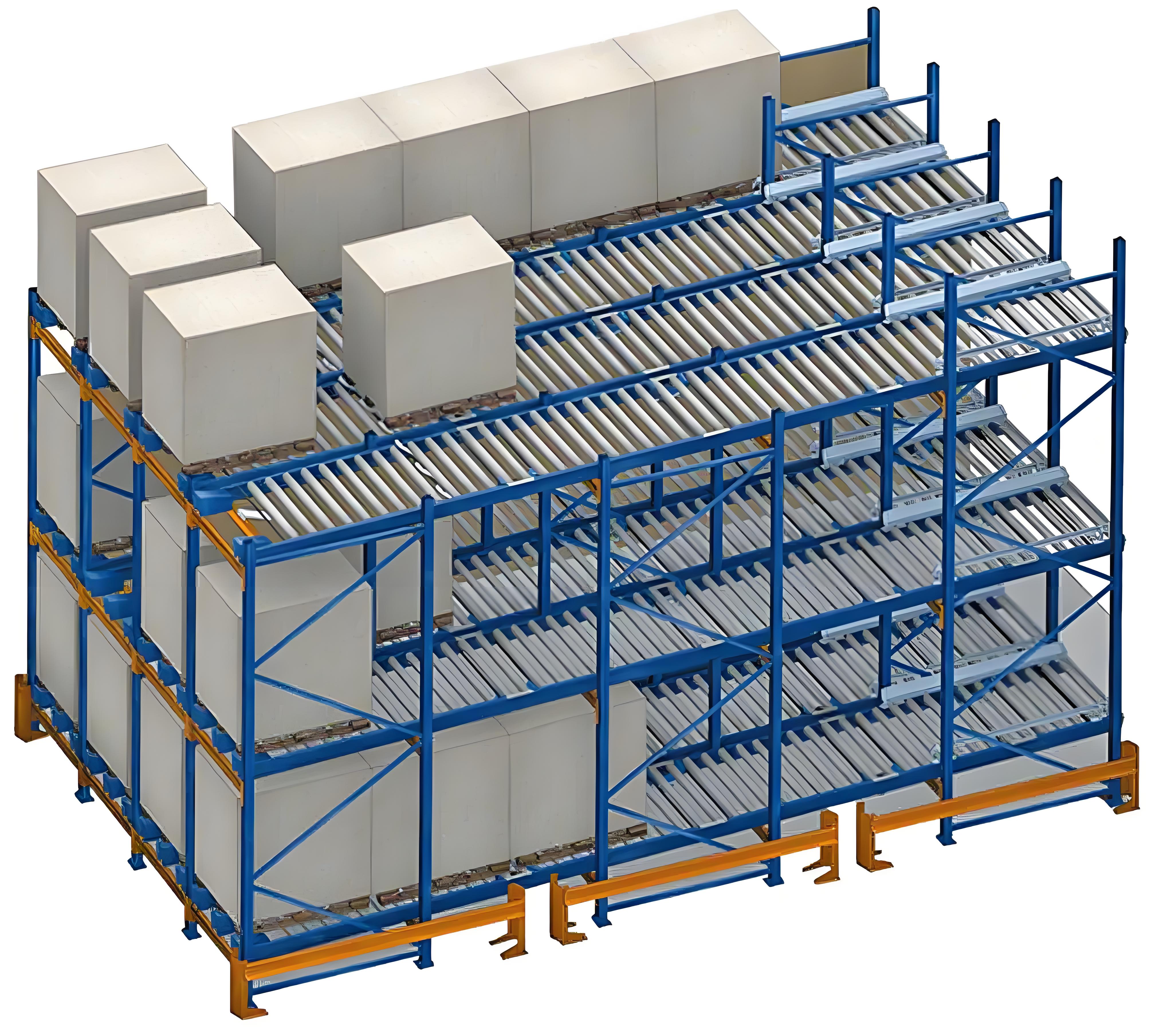

★ Compatible with 2-way, 4-way or 6-way shuttle cars, mother-child vehicles, forklifts, and stackers, it offers higher storage density than push-back or gravity racks. It supports flexible FIFO or LIFO operation modes, enabling seamless semi-automatic or fully automated storage solutions. This makes it an efficient alternative to short-term storage and drive-in shelving.

★ Widely applied across industries, especially ideal for sectors with large volumes but few SKUs, such as food, beverage, chemical, and tobacco industries with predominantly single or limited product varieties.

Advantages of the Shuttle Racking System

High Storage Density: Maximizes warehouse space by reducing aisle requirements compared to traditional shelving.

Automated and Semi-Automated Operation: Supports integration with shuttle cars and automated vehicles, improving efficiency and reducing labor costs.

Flexible Storage Modes: Allows both FIFO (First In, First Out) and LIFO (Last In, First Out) inventory management to suit different operational needs.

Improved Handling Speed: Speeds up loading and unloading processes with automated shuttle movement, boosting throughput.

Enhanced Safety: Minimizes forklift traffic inside racks, reducing accident risks and damage to goods.

Suitable for Large Volumes with Limited SKU Variety: Ideal for industries with bulk storage needs and relatively few product types, such as food, beverage, chemical, and tobacco sectors.

Scalable and Customizable: Easily adapts to different warehouse layouts and can be expanded or modified as storage needs evolve.

Why Choose HEGERLS Shuttle Racks

With decades of experience in planning and designing logistics systems worldwide, HEGERLS delivers proven, high-performance storage solutions.

Our shuttle racking systems maximize warehouse space and dramatically improve throughput while reducing labor and handling time.

Backed by our strong production base and strict quality control, HEGERLS racks ensure durability, safety, and long service life.

Key words:

Previous Page:

Next page:

Related Solutions

Shuttle + Forklift (AGV forklift) Intelligent Intensive Storage System and Solutions

Shuttle + stacker crane intelligent dense storage system and solution

Shuttle car & carrier + lift intelligent dense storage system and solution

Related Products

Product free consultation

HEGERLS has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955

MOBILE: +86 133 1595 3337

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2025 Hebei Woke Metal Products Co., ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home