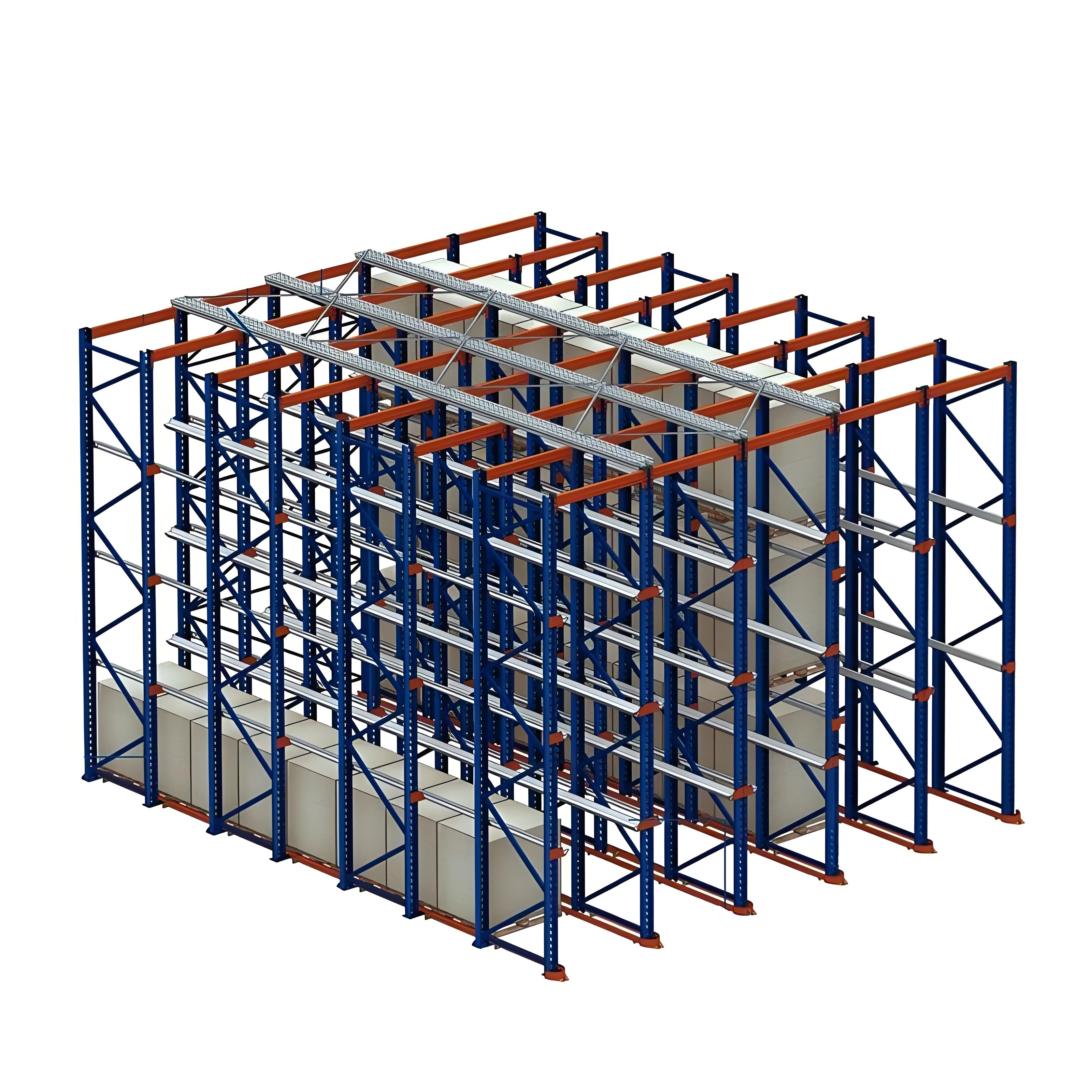

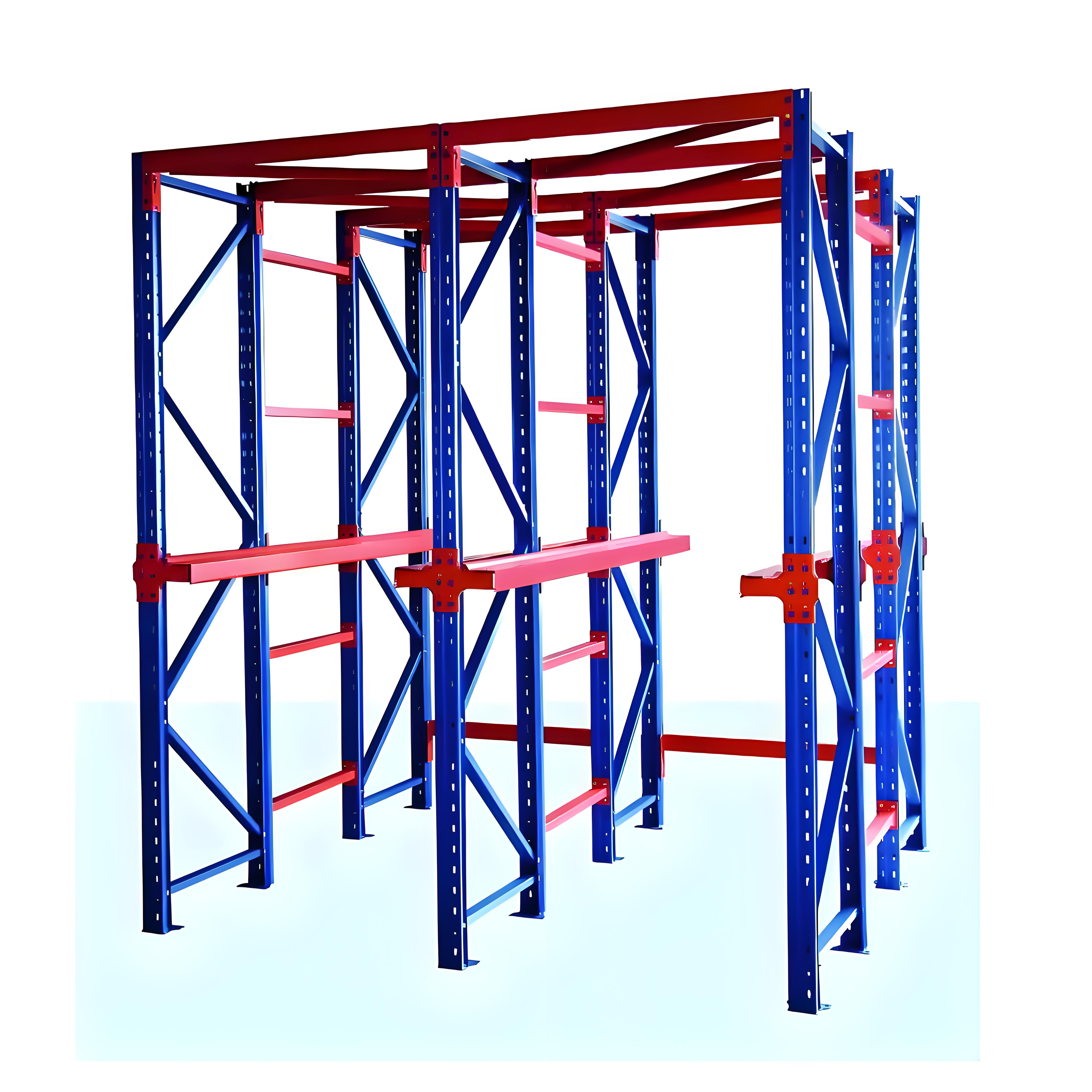

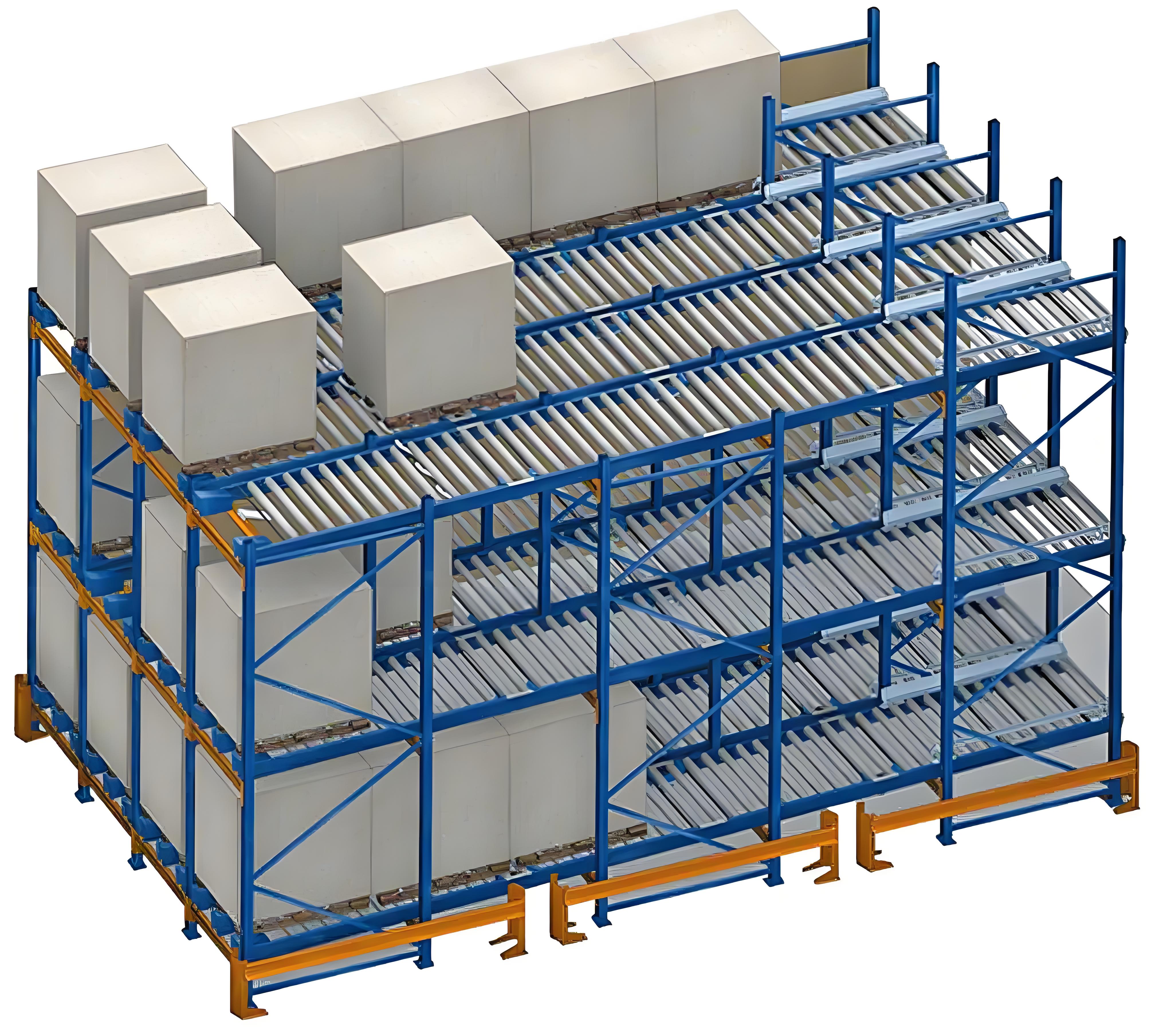

Drive-in racks

Classification:

Application:

Detailed introduction

Key Features and Advantages of HEGERLS Drive-in Racking/ Drive-through Racking

★ Maximized Storage Density: Single-sided access drive-in rackings hold up to 7 pallets deep, while double-sided drive-through systems extend to 15 pallets deep, making them ideal for high-capacity, space-saving storage.

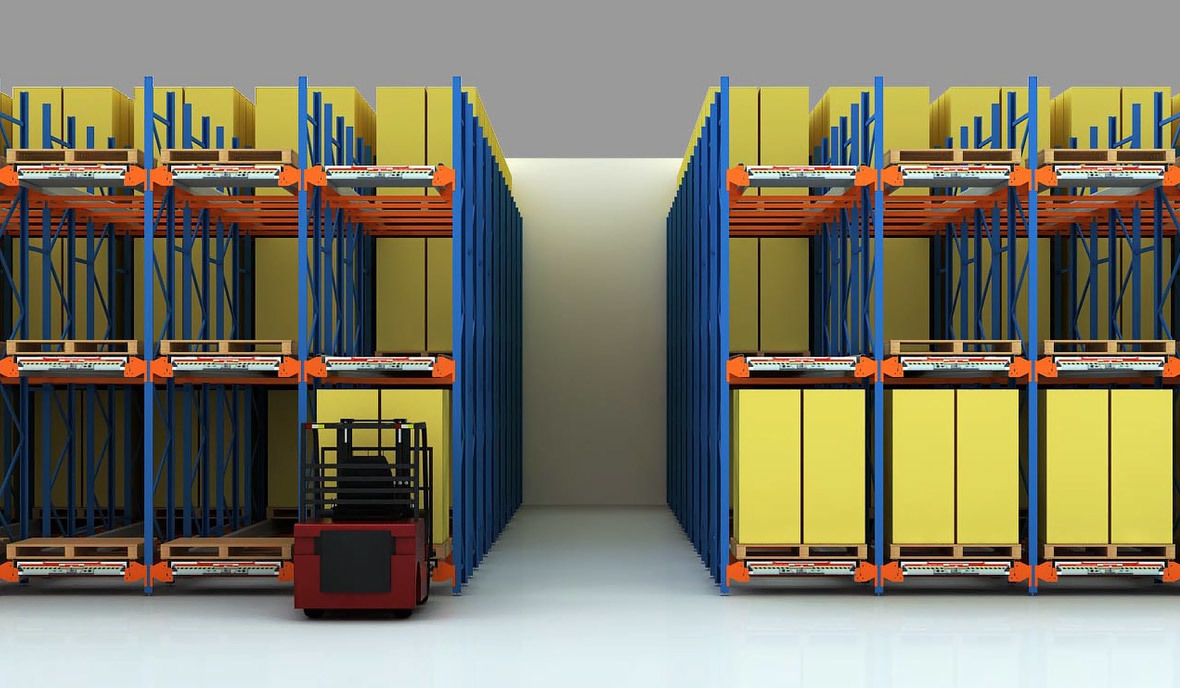

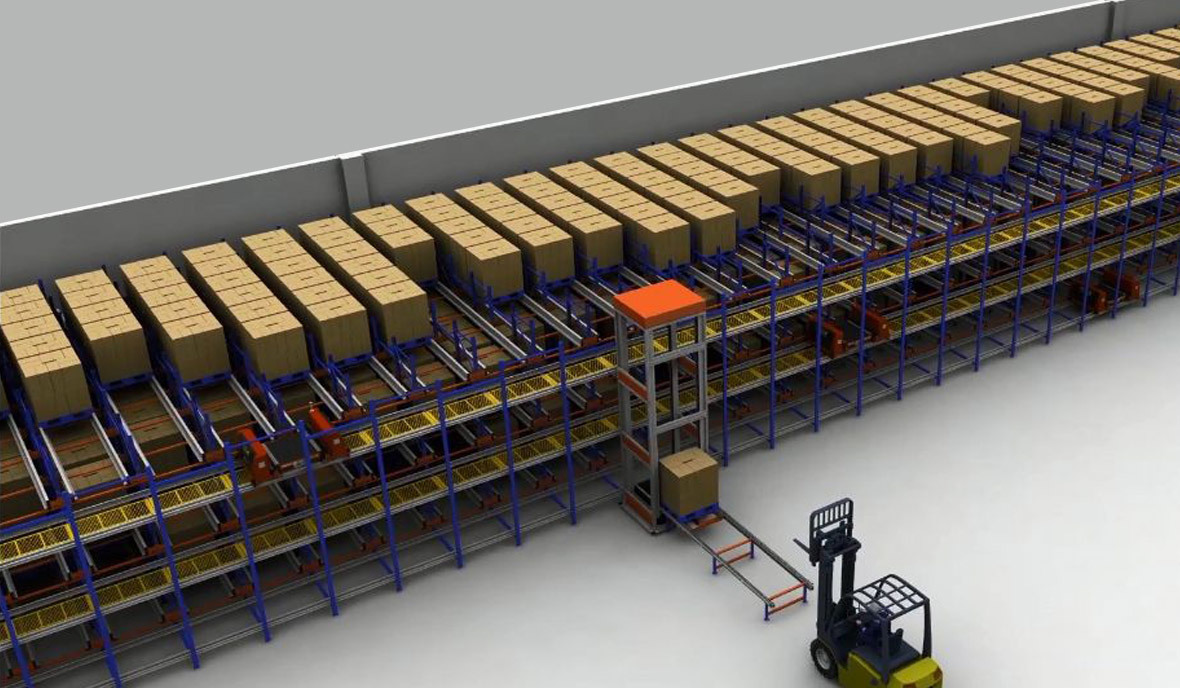

★ Flexible Dual Modes to Match Different Inventory Needs: Single-side access drive-in racking loads and unloads goods from the same side, following the Last-In, First-Out (LIFO) principle. Ideal for bulk goods with long shelf life and slower turnover, such as seasonal stock or raw materials. Simple operation with higher lane utilization. Dual-access drive-through racking allows loading from one side and unloading from the other, enabling First-In, First-Out (FIFO) rotation. Perfect for time-sensitive products like food and pharmaceuticals, ensuring strict inventory rotation. Commonly used as a buffer warehouse between production and shipping, seamlessly linking the supply chain.

★ Built for Skilled Operations: Forklift operations generally follow a continuous “high lift, high operation" mode. As pallets are lifted high, the forklift prone to shaking or colliding with racks due to uneven flooring in the channels. While this system requires trained operators, it ensures safe and stable pallet handling in deep-lane storage.

★ Lower Investment, Higher Return: By reducing aisles and maximizing storage density, drive-in racks use 15–20% less steel compared to other rack systems. Over time, they deliver the lowest cost per pallet position among high-bay racking systems, ensuring long-term ROI.

★ Simplified Inventory Management, Reduced Operational Complexity: Each racking lane stores a single SKU with clear categorization, allowing warehouse staff to quickly locate inventory, count quantities, and reduce errors from mixed SKUs. In cold storage, this simplified workflow also minimizes exposure to ambient temperatures, helping to ensure product quality.

★ 100% Customizable for Any Storage Scenario: Whether storing lightweight cartons or heavy industrial components, standard pallets or oversized, non-standard pallets, the system can be fully customized by adjusting lane depth, rack height, and support rail types to create a tailored solution for each warehouse. For example, low-temperature steel components can be used for cold storage warehouses, while additional rack levels can be added for lightweight goods like daily chemicals to maximize space utilization.

Suitable Scenarios for Drive-In & Drive-Through Racking Systems

Large Volume, Low-SKU Storage: Ideal for beverage factories, food processing, and building materials, consolidating similar goods, reducing space waste, and improving forklift efficiency.

High-Rent Urban Warehouses: Maximizes storage density in limited space, reducing per-unit storage costs in expensive urban logistics centers.

Cold Storage & Low-Temperature Warehouses: Compact layouts minimize non-storage areas, reduce cooling load, and save energy. Drive-through racks serve as a buffer zone to reduce temperature exchange.

Supply Chain Buffer Warehouses: FIFO drive-through racks enable fast in-and-out turnover, supporting temporary storage between production, quality control, and shipping, shortening supply chain response times.

High-Security or Heavy Load Storage: Robust rack design can handle oversized or heavy industrial components while maintaining safety and stability, suitable for manufacturing and industrial warehouses.

Flexible Seasonal Storage: Perfect for seasonal products or promotional stock, allowing warehouses to adjust layout and lane depth to accommodate changing inventory volumes efficiently.

Case Study

Drive-in / Drive-through Racks from HEGERLS

Key words:

drive in racking

drive in pallet racking

drive in warehouse racking

drive thru racking

Previous Page:

Next page:

Related Solutions

Shuttle + Forklift (AGV forklift) Intelligent Intensive Storage System and Solutions

Shuttle + stacker crane intelligent dense storage system and solution

Shuttle car & carrier + lift intelligent dense storage system and solution

Related Products

Product free consultation

HEGERLS has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955