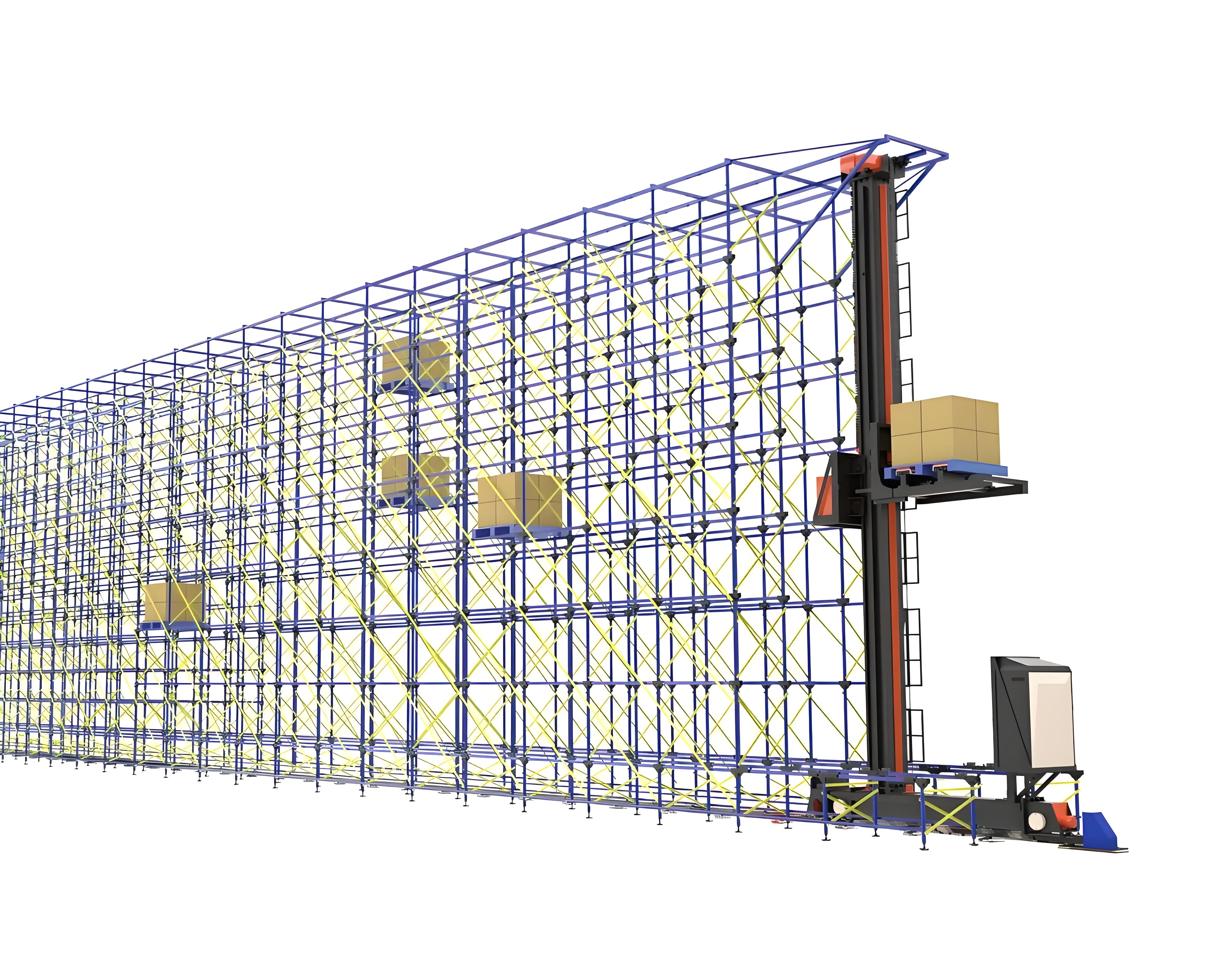

Shuttle + stacker crane intelligent dense storage system and solution

Classification:

Application:

Introduction

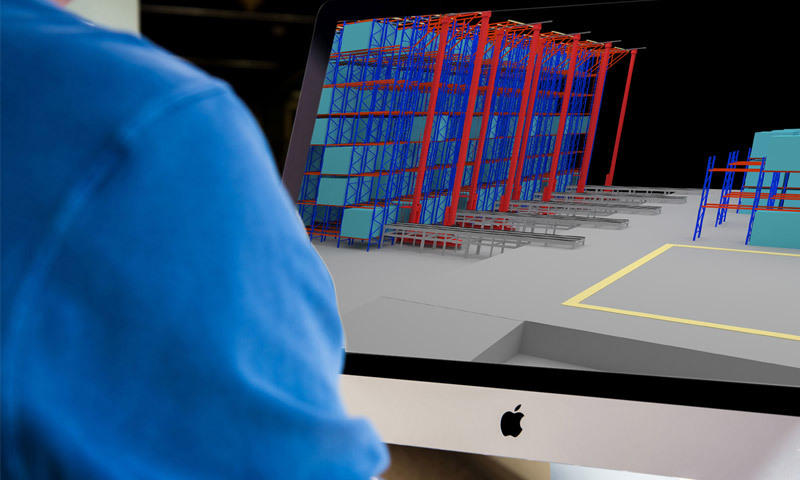

The system is a highly automated warehousing solution that integrates the advantages of shuttle trucks and stacker cranes to achieve high-density storage and efficient circulation of goods. The core principle lies in:

Stacker crane: responsible for the vertical and horizontal transportation of the main aisle, and completing the storage and retrieval of goods at the aisle port.

Shuttle bus: Horizontal transportation is carried out in the sub aisle to accurately deliver goods to designated locations.

WMS/WCS scheduling system: Implement collaboration between the two, ensuring efficient connection of tasks through path planning and task allocation.

Shuttle Configuration Option

| Category | Function description | Remarks |

| Standard | Domestic servo motor, speed 1.0~1.5m/s, positioning accuracy ± 3mm, low cost | Room temperature storage, general cargo |

| Advanced | Imported brushless servo motor, speed 1.5m/s, maintenance free; AI obstacle avoidance+LiDAR collision prevention | High frequency operations, precision manufacturing industry |

| Low temperature | Cold and moisture-proof design for components, anti freezing treatment for batteries, normal operation at -30 ℃ | Cold chain warehouse (below -25 ℃) |

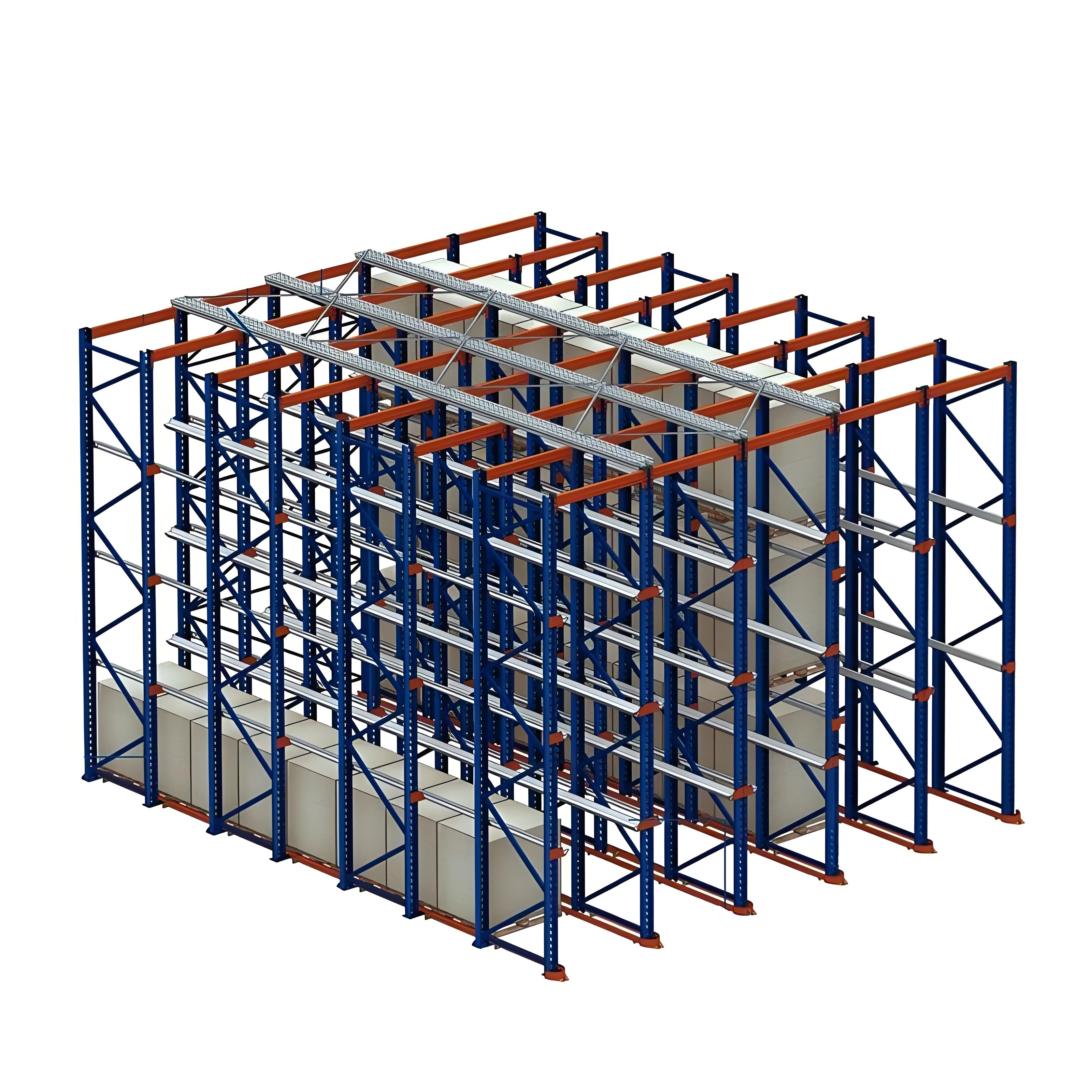

| AS/RS | Ultra thin design (≤ 126mm), supporting collaboration with stacker cranes; Wireless communication+online charging | Automated stereoscopic library integration |

Solution advantages

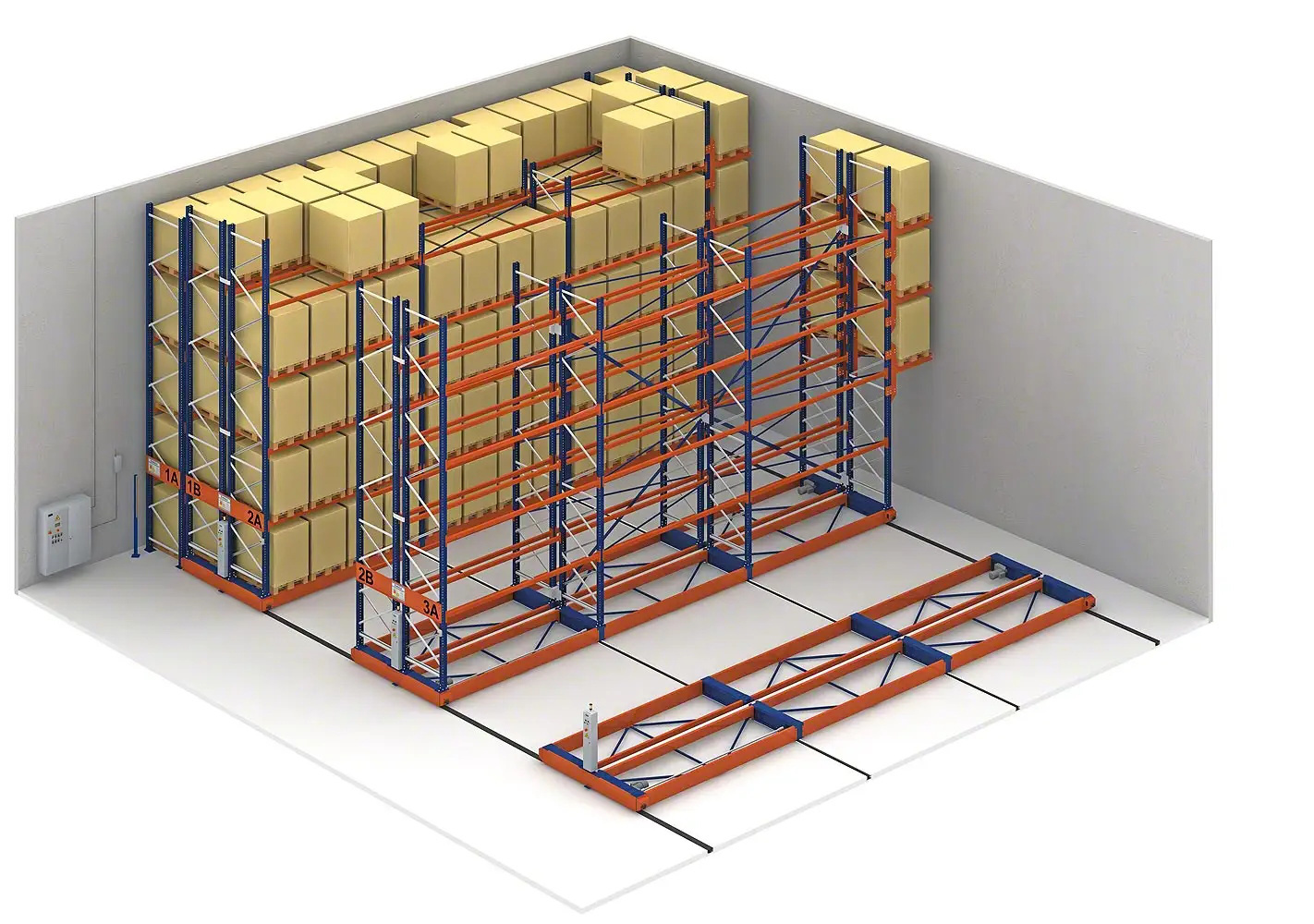

★ High flexibility: The shuttle car can operate in various levels and tunnels, and compared to the traditional stacker crane that can only operate in fixed tunnels, the system has higher flexibility and stronger adaptability.

★ Data integration and management: WMS and WCS systems synchronize data in real time to achieve inventory visualization and information traceability, support RFID technology, and achieve full process tracking of goods from production to delivery, ensuring food safety and anti-counterfeiting.

★ Strong scalability: The system has high scalability for later inventory efficiency, and can be flexibly expanded according to business growth to protect enterprise investment.

★ Simplify system structure: Stacker cranes have replaced shuttle buses and vertical hoists, simplifying horizontal and vertical handling processes, making the system structure more concise and efficient.

★ Full automation and safety: Eliminating manual forklift operations, reducing collision risks and human errors, and lowering labor intensity and safety accident rates.

Key words:

Strength Guarantee

R & D

R & D

Design

Design

Production

Production

Quality

Quality

There are more than 10 patented technologies in three major intelligent storage equipment, such as shuttles, stackers, and mobile racks. we have nearly 60 senior technicians and senior engineers.

★ Shuttle runner

1. Large tonnage lifting patent technology, easy to achieve 3 tons load

2. Intensive storage experts, achieving cost reduction and efficiency high-density storage

★ Stacker crane

1. Stacker crane has green energy storage technology

2. Unique intelligent storage plate multi-category sorting patent technology, flexible realization of convenient plate sorting.

★ Intelligent mobile rack system

8tons and Seismic. Unique design of 16 tons load, Provide storage security for earthquake-prone areas.

...

★Designers help product appearance, architecture, performance, program planning and design high quality landing;

★Provide one-stop warehousing projects, logistics park technology, equipment integration services;

★Provide 24-hour emergency response mechanism for medicine, refrigeration, military supplies and other special industries and special projects

★60000 ㎡ production base, 300 + team assistance, 48 world advanced environmental protection production lines;

★Independent research and development, design, production, sales, installation, after-sales service, one-stop integration and service;

★Products and services cover more than 30 provinces, municipalities and autonomous regions in China, and are exported to more than 110 countries and regions such as Europe, America, the Middle East, Latin America, and Southeast Asia.

★For more than 20 years, the independent brand "Highgris HEGERLS" has won various honorary awards at home and abroad for many times;

★Brand products involve intelligent storage automation equipment and management control system software, storage shelves and peripheral supporting equipment, business super series 5 categories, more than 40 classified products and services;

★Products through SGS, BV, TUV international product quality inspection agency certification, ISO9001 quality management and environmental protection system certification;

Successful Projects

Algeria FACTO Group Storage Project

Hebei Dingzhou Garrison Reserve Grain Depot Shuttle Car Shelf System Storage Project

Sweden's SWEDMART company's crossbeam warehouse project

Related Products

Scheme customization

Highgeris has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955