Shuttle + Forklift Intelligent Intensive Storage System and Solutions

Classification:

Application:

Introduction

This system is a high-density storage solution that combines shuttle cars, forklifts, and shuttle shelves, suitable for multiple industries such as e-commerce logistics, food and dairy, refrigeration, and automotive parts. The system achieves high-density storage and efficient inbound and outbound operations through the automatic handling of shuttle cars on shelf tracks, combined with the end pickup of forklifts. The system supports two modes: semi-automatic and fully automatic:

Semi automatic mode: Remote monitoring of shuttle vehicles through handheld terminals, with minimal investment and easy management.

Fully automatic mode: Combined with management control system software (WMS/WCS) and AGV forklift equipment, it achieves unmanned operation with high precision and maintenance requirements.

Shuttle Configuration Option

| Category | Function description | Remarks |

| Standard | Domestic servo motor, speed 1.0~1.5m/s, positioning accuracy ± 3mm, low cost | Room temperature storage, general cargo |

| Advanced | Imported brushless servo motor, speed 1.5m/s, maintenance free; AI obstacle avoidance+LiDAR collision prevention | High frequency operations, precision manufacturing industry |

| Low temperature | Cold and moisture-proof design for components, anti freezing treatment for batteries, normal operation at -30 ℃ | Cold chain warehouse (below -25 ℃) |

| AS/RS | Ultra thin design (≤ 126mm), supporting collaboration with stacker cranes; Wireless communication+online charging | Automated stereoscopic library integration |

Solution advantages

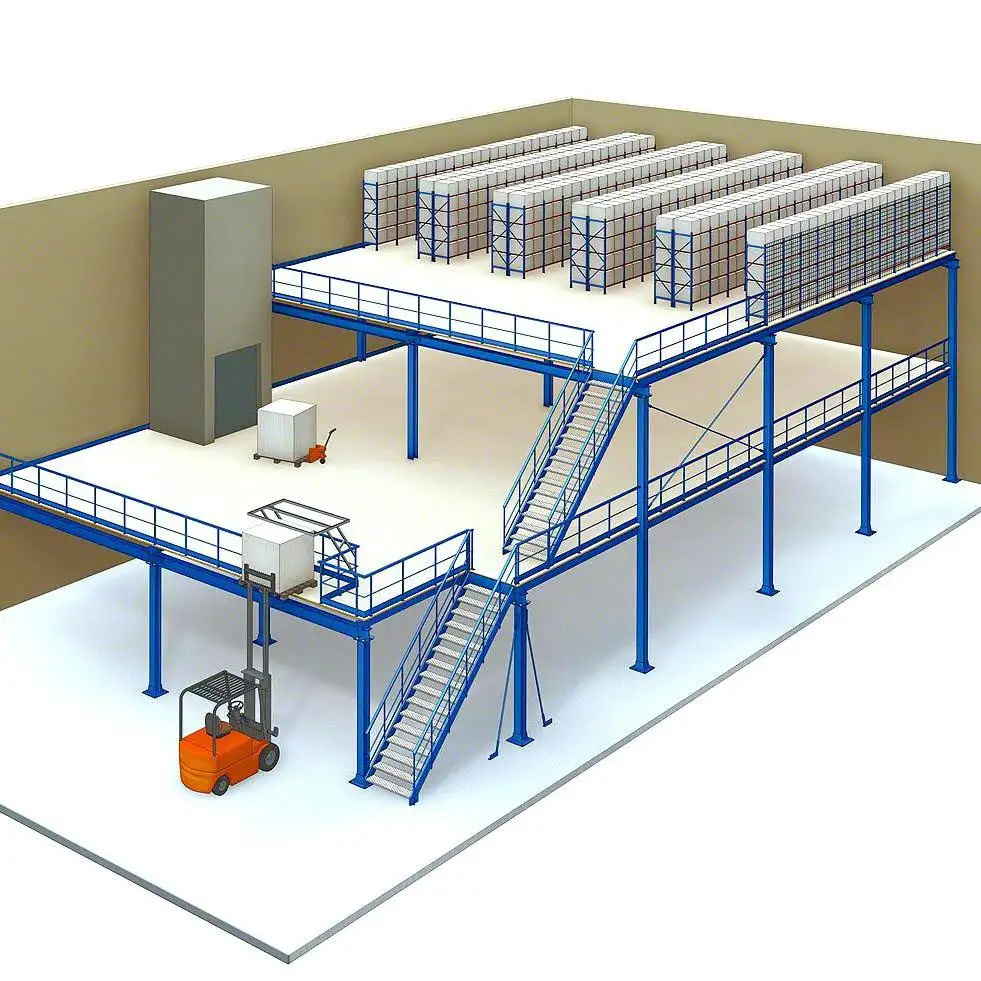

1. Space utilization improvement: By adopting a dense storage layout, the warehouse's flat and vertical space can be maximized, resulting in a storage density increase of over 80% compared to traditional shelves.

2. Improved operational efficiency: Cache and picking positions are added as needed at the inbound and outbound ports to achieve edge picking and main channel outbound, minimizing the number of reversals, shortening the handling distance, and increasing system response speed, greatly improving cargo storage and retrieval efficiency.

3. Intelligent management: The shuttle car reserves an interface with the warehouse management system WMS to achieve real-time data synchronization, supporting both semi-automatic and fully automatic operation modes, and adapting to different stages of automation requirements.

4. Flexible scalability: In order to improve space utilization and automation to a greater extent, a mother child shuttle design can be adopted. In addition to the standard version, the four-way shuttle can be customized according to the pallet size to adapt to different cargo specifications.

5. Strong industry adaptability: widely applicable to various industries, including e-commerce, cold chain logistics, food and beverage, fast-moving consumer goods, pharmaceutical distribution, tobacco warehousing, etc.

Key words:

Next page:

Strength Guarantee

R & D

R & D

Design

Design

Production

Production

Quality

Quality

There are more than 10 patented technologies in three major intelligent storage equipment, such as shuttles, stackers, and mobile racks. we have nearly 60 senior technicians and senior engineers.

★ Shuttle runner

1. Large tonnage lifting patent technology, easy to achieve 3 tons load

2. Intensive storage experts, achieving cost reduction and efficiency high-density storage

★ Stacker crane

1. Stacker crane has green energy storage technology

2. Unique intelligent storage plate multi-category sorting patent technology, flexible realization of convenient plate sorting.

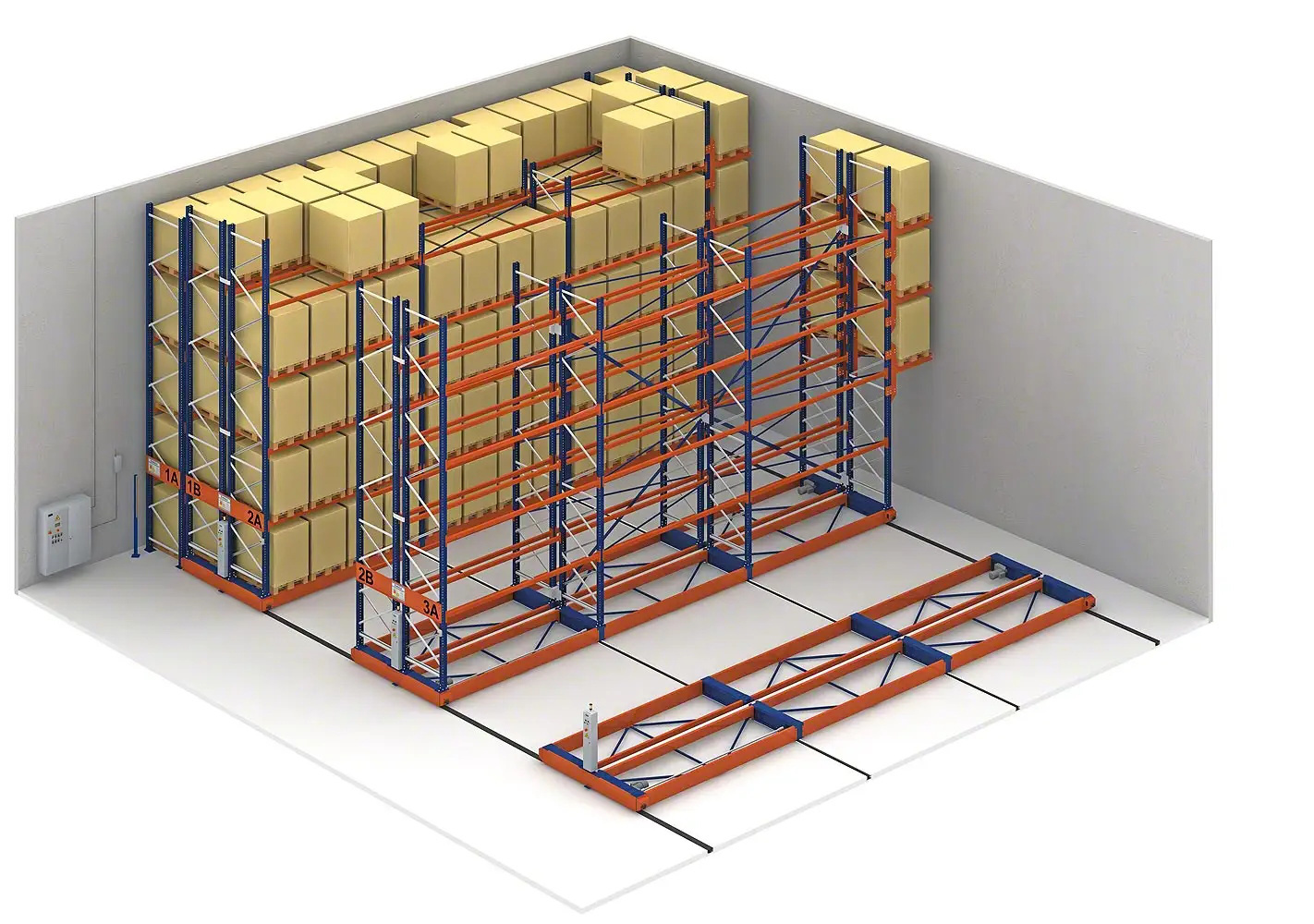

★ Intelligent mobile rack system

8tons and Seismic. Unique design of 16 tons load, Provide storage security for earthquake-prone areas.

...

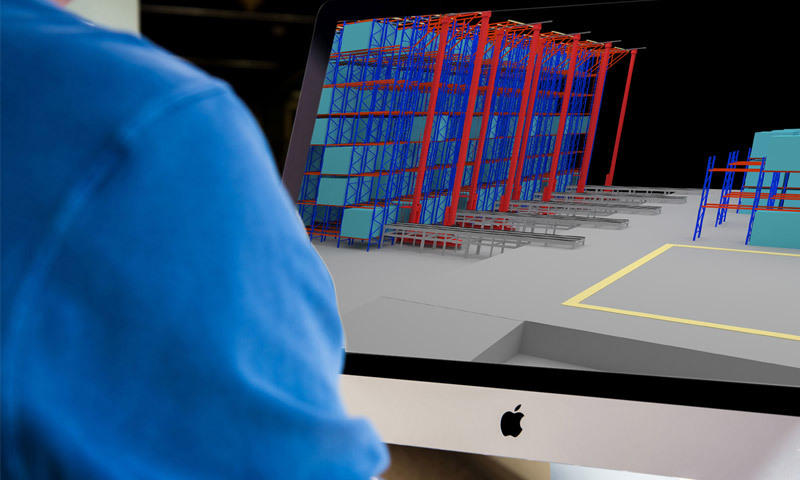

★Designers help product appearance, architecture, performance, program planning and design high quality landing;

★Provide one-stop warehousing projects, logistics park technology, equipment integration services;

★Provide 24-hour emergency response mechanism for medicine, refrigeration, military supplies and other special industries and special projects

★60000 ㎡ production base, 300 + team assistance, 48 world advanced environmental protection production lines;

★Independent research and development, design, production, sales, installation, after-sales service, one-stop integration and service;

★Products and services cover more than 30 provinces, municipalities and autonomous regions in China, and are exported to more than 110 countries and regions such as Europe, America, the Middle East, Latin America, and Southeast Asia.

★For more than 20 years, the independent brand "Highgris HEGERLS" has won various honorary awards at home and abroad for many times;

★Brand products involve intelligent storage automation equipment and management control system software, storage shelves and peripheral supporting equipment, business super series 5 categories, more than 40 classified products and services;

★Products through SGS, BV, TUV international product quality inspection agency certification, ISO9001 quality management and environmental protection system certification;

Successful Projects

Hebei Dingzhou Garrison Reserve Grain Depot Shuttle Car Shelf System Storage Project

Sweden's SWEDMART company's crossbeam warehouse project

Cross beam shelving storage project in the supermarket logistics park

Related Products

Scheme customization

Highgeris has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955