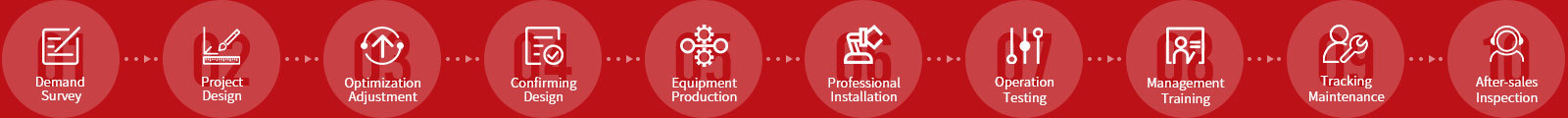

Shuttle car & carrier + lift intelligent dense storage system and solution

Classification:

Application:

Introduction

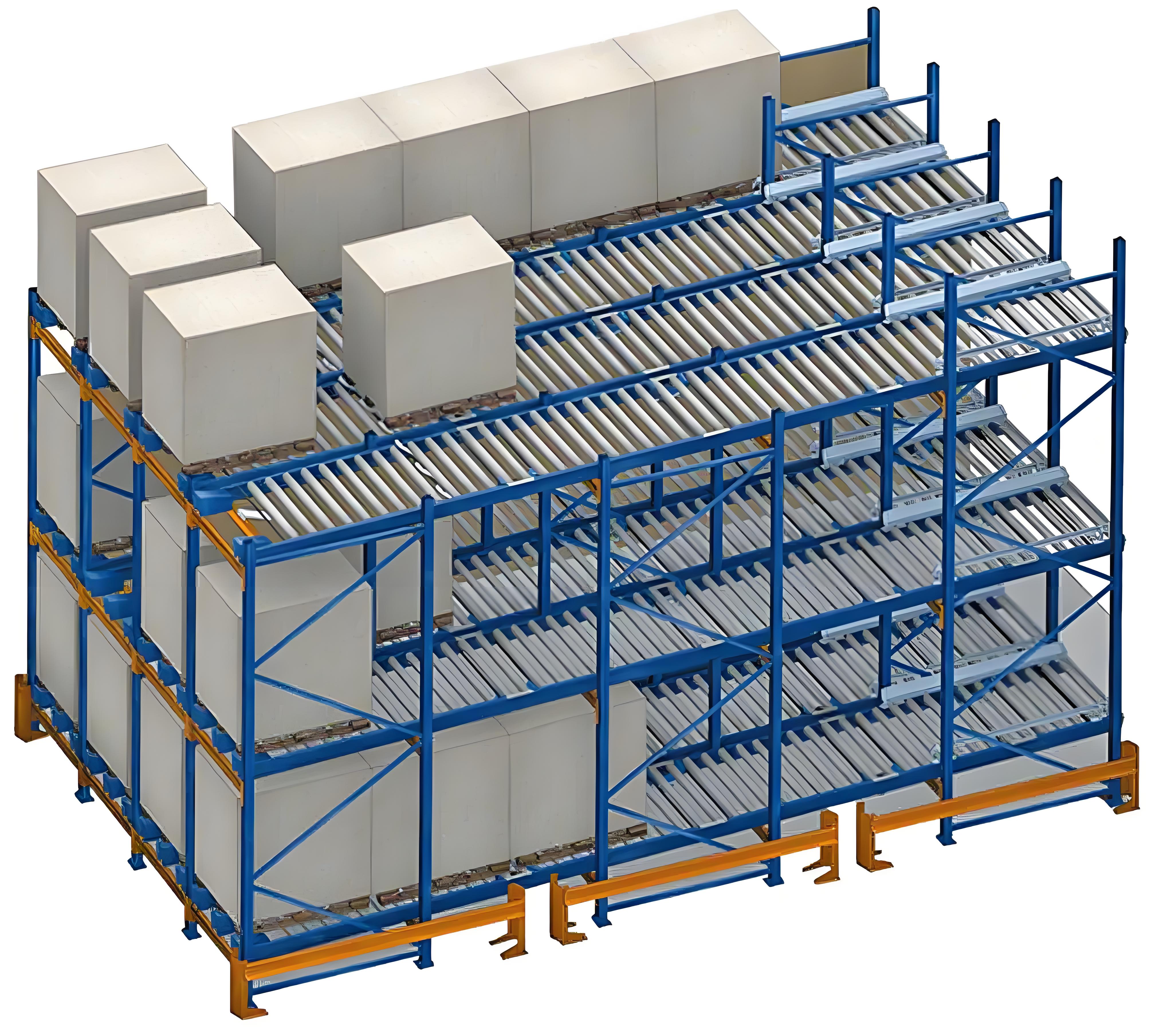

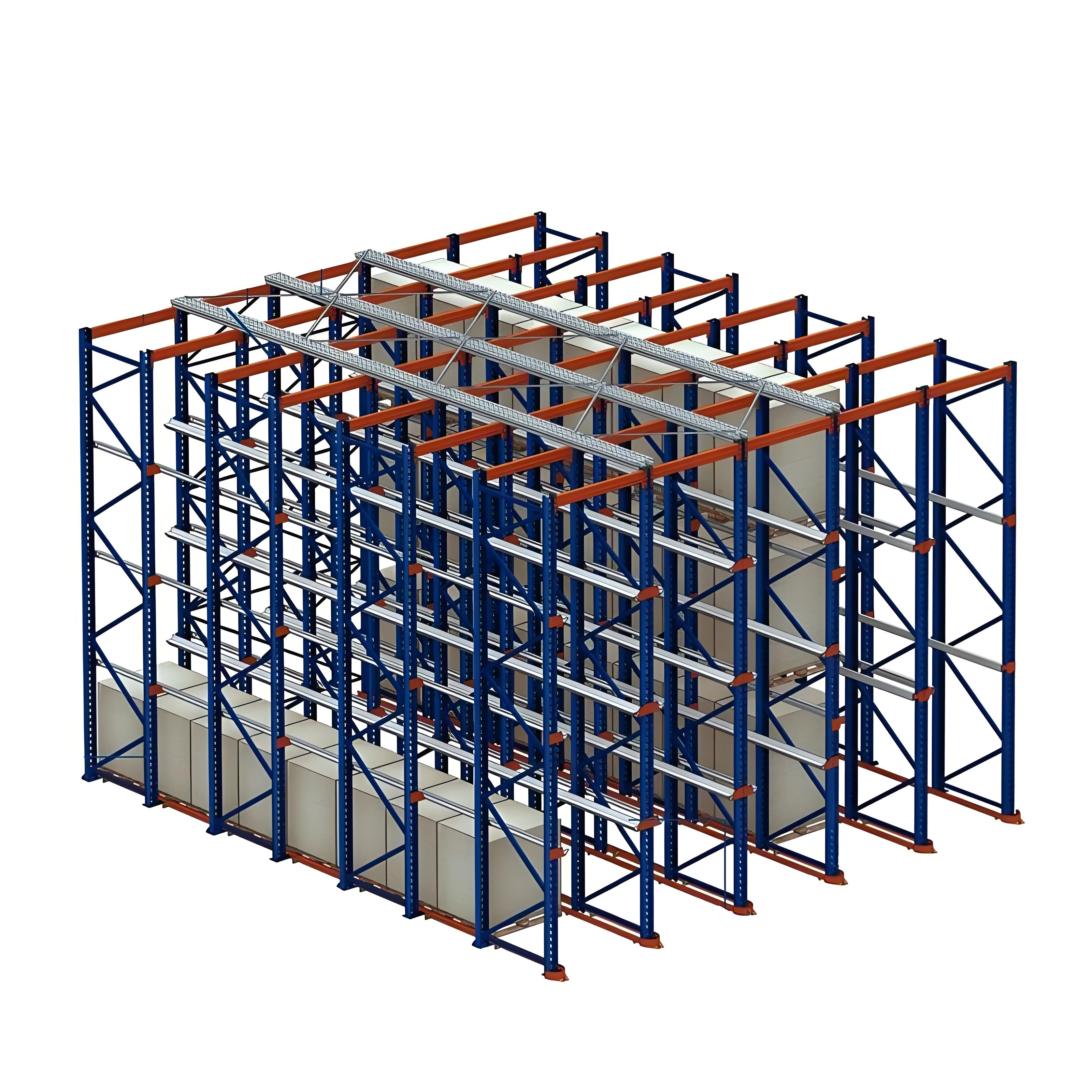

Features: This system is the most typical application system in the field of intelligent dense storage. It has high storage density, high storage and retrieval efficiency, stable operation system , high expandability for later need.

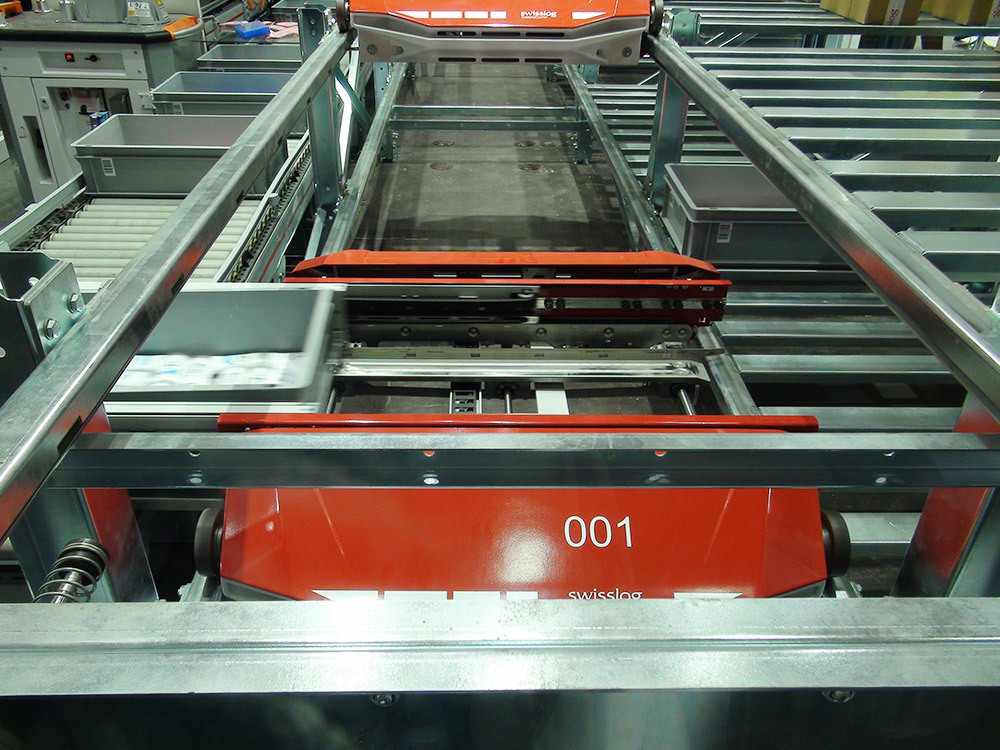

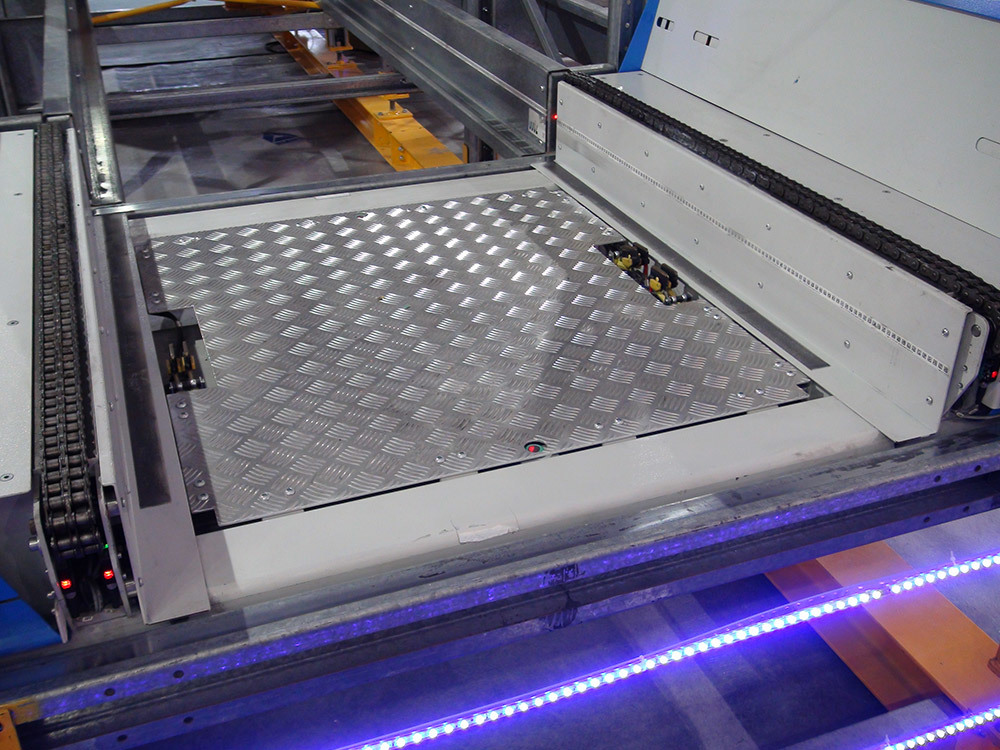

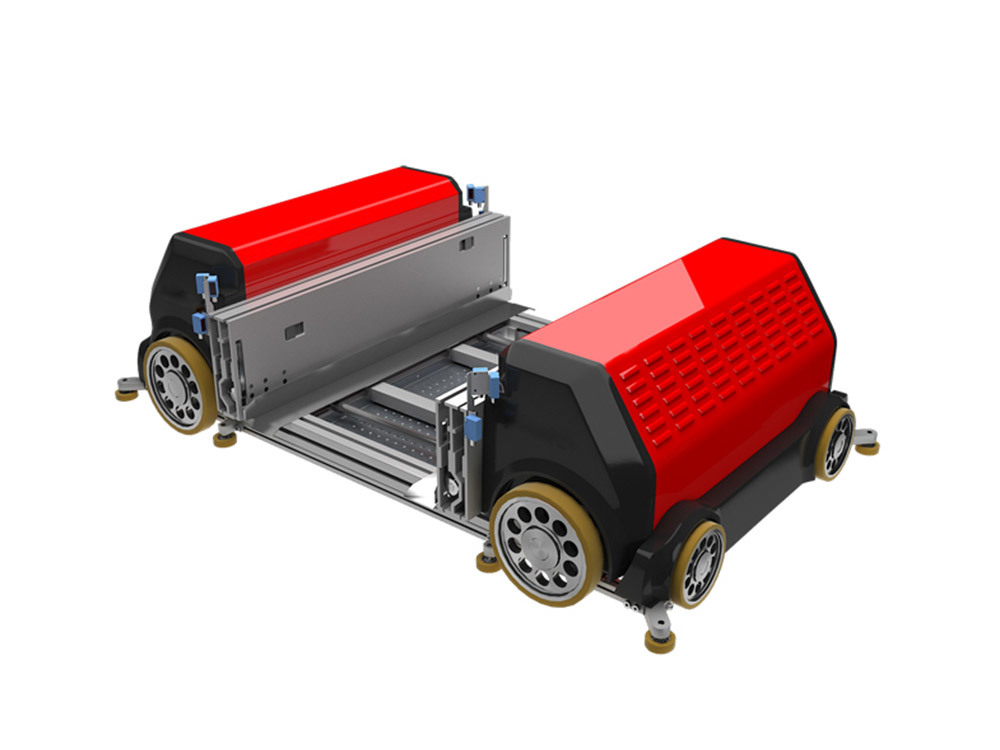

Composition: The system consists of a shuttle car, a shuttle carrier, a fast vertical lift, a horizontal conveying system, a racking system, and a WMS/WCS management and control system. The shuttle car is responsible for the transportation of the storage roadway, the shuttle carrier is responsible for the transportation of the lateral transfer roadway, and the fast hoist and conveying system are responsible for the vertical and horizontal transportation of the ground floor. Each single shuttle and equipment are connected with each other under the support of wireless network, and under the scheduling of the WMS & WCS upper management, they respond to each other to complete goods entry and exit in the first-in-first-out or first-in-last-out mode.

Application: It is widely used in food, beverage, dairy, medicine, tobacco, chemicals and other products, and is suitable for low-temperature cold chain logistics.

Shuttle Configuration Option

| Category | Function description | Remarks |

| Standard | Domestic servo driver, brushed servo motor, domestic remote control | Standard configuration |

| Advanced | Imported driver, imported motor, imported remote control | All imported configuration |

| Low temperature | The system adopts anti-low temperature and moisture-proof design, and the components are all low-temperature resistant models, which can work normally at -25℃, four-wheel &four-wheel drive. | Absolute low temperature without heating |

Solution advantages

1.High level of automation, high storage density, high storage efficiency

2.Four directions, track change in place, direct to all locations

3.WMS/WCS system dispatches the shuttle & carrier operation, monitors it position, the speed, the electricity level in real time

Key words:

Strength Guarantee

R & D

R & D

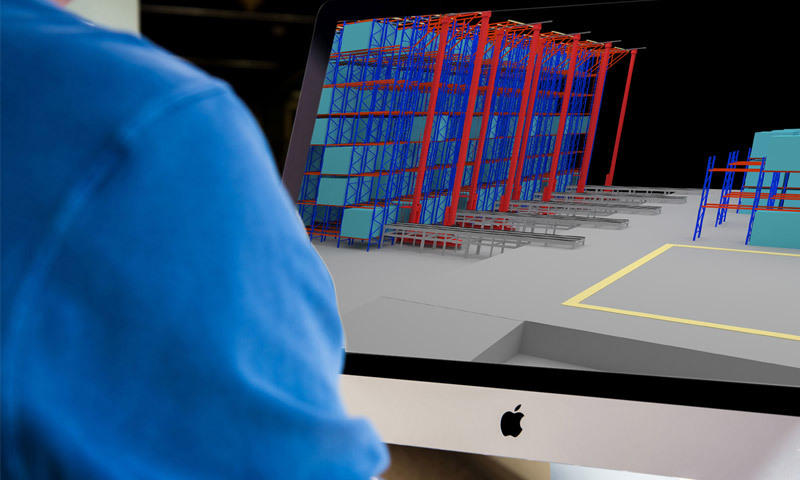

Design

Design

Production

Production

Quality

Quality

There are more than 10 patented technologies in three major intelligent storage equipment, such as shuttles, stackers, and mobile racks. we have nearly 60 senior technicians and senior engineers.

★ Shuttle runner

1. Large tonnage lifting patent technology, easy to achieve 3 tons load

2. Intensive storage experts, achieving cost reduction and efficiency high-density storage

★ Stacker crane

1. Stacker crane has green energy storage technology

2. Unique intelligent storage plate multi-category sorting patent technology, flexible realization of convenient plate sorting.

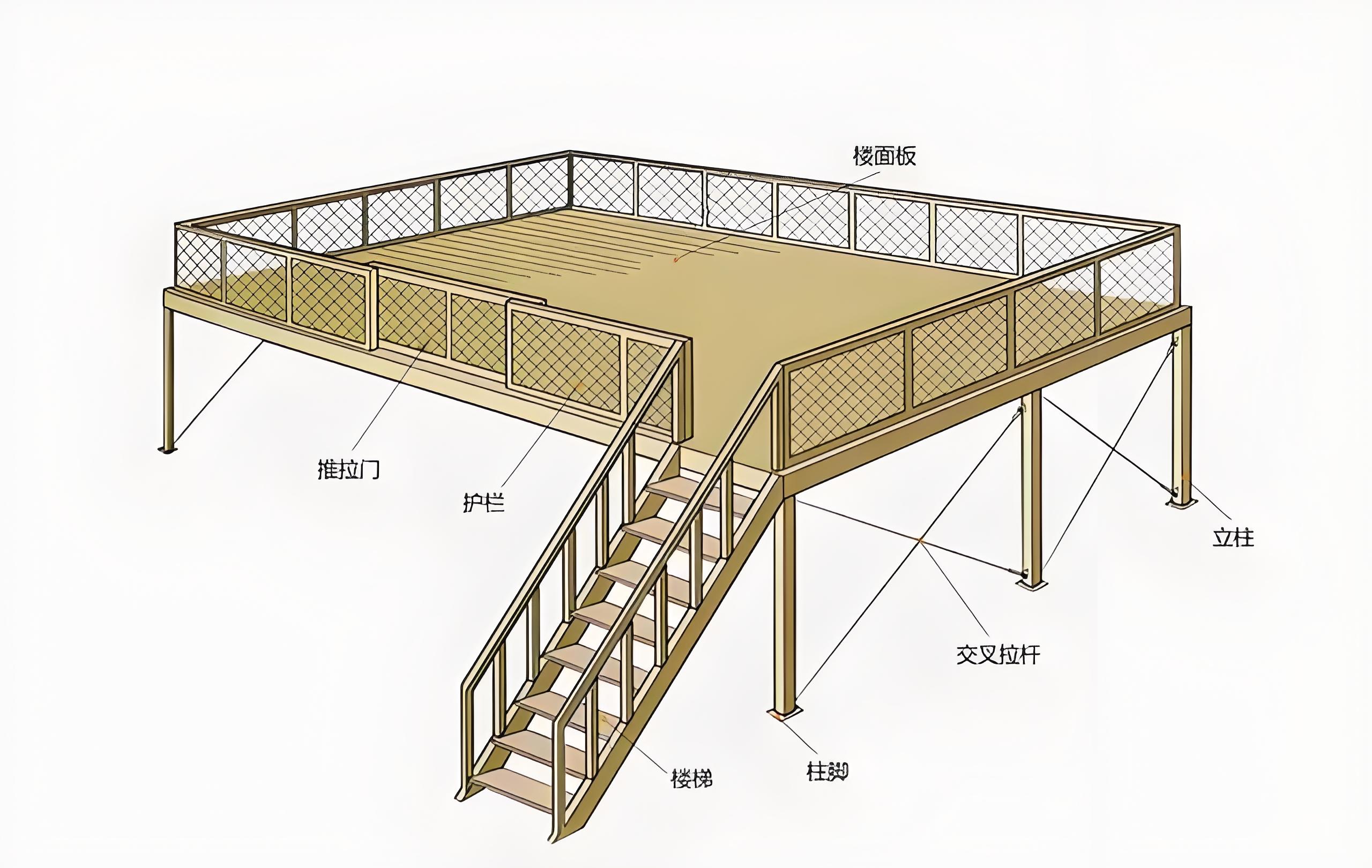

★ Intelligent mobile rack system

8tons and Seismic. Unique design of 16 tons load, Provide storage security for earthquake-prone areas.

...

★Designers help product appearance, architecture, performance, program planning and design high quality landing;

★Provide one-stop warehousing projects, logistics park technology, equipment integration services;

★Provide 24-hour emergency response mechanism for medicine, refrigeration, military supplies and other special industries and special projects

★60000 ㎡ production base, 300 + team assistance, 48 world advanced environmental protection production lines;

★Independent research and development, design, production, sales, installation, after-sales service, one-stop integration and service;

★Products and services cover more than 30 provinces, municipalities and autonomous regions in China, and are exported to more than 110 countries and regions such as Europe, America, the Middle East, Latin America, and Southeast Asia.

★For more than 20 years, the independent brand "Highgris HEGERLS" has won various honorary awards at home and abroad for many times;

★Brand products involve intelligent storage automation equipment and management control system software, storage shelves and peripheral supporting equipment, business super series 5 categories, more than 40 classified products and services;

★Products through SGS, BV, TUV international product quality inspection agency certification, ISO9001 quality management and environmental protection system certification;

Successful Projects

Cross beam shelving storage project in the supermarket logistics park

Xinzhou Yuncang Smart Warehouse Project

Thailand Jinming Group Shuttle Vehicle Storage Project

Related Products

Scheme customization

Highgeris has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955