-

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogIn recent years, Haigelis has designed, manufactured, and installed a series of warehousing and logistics projects for well-known domestic companies such as Sinopec, PetroChina, Coca-Cola, Yihai Kerry, Alibaba Cainiao Logistics, Junlebao, Jinmailang, North China Pharmaceutical, Lucky Film, YTO Express, and Inner Mongolia Xinhua Publishing and Distribution Group.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

Mezzanine Racking: Revolutionizing Vertical Space for Warehouse Efficiency

Classification:

Industry Info

Release time:

2025-07-22

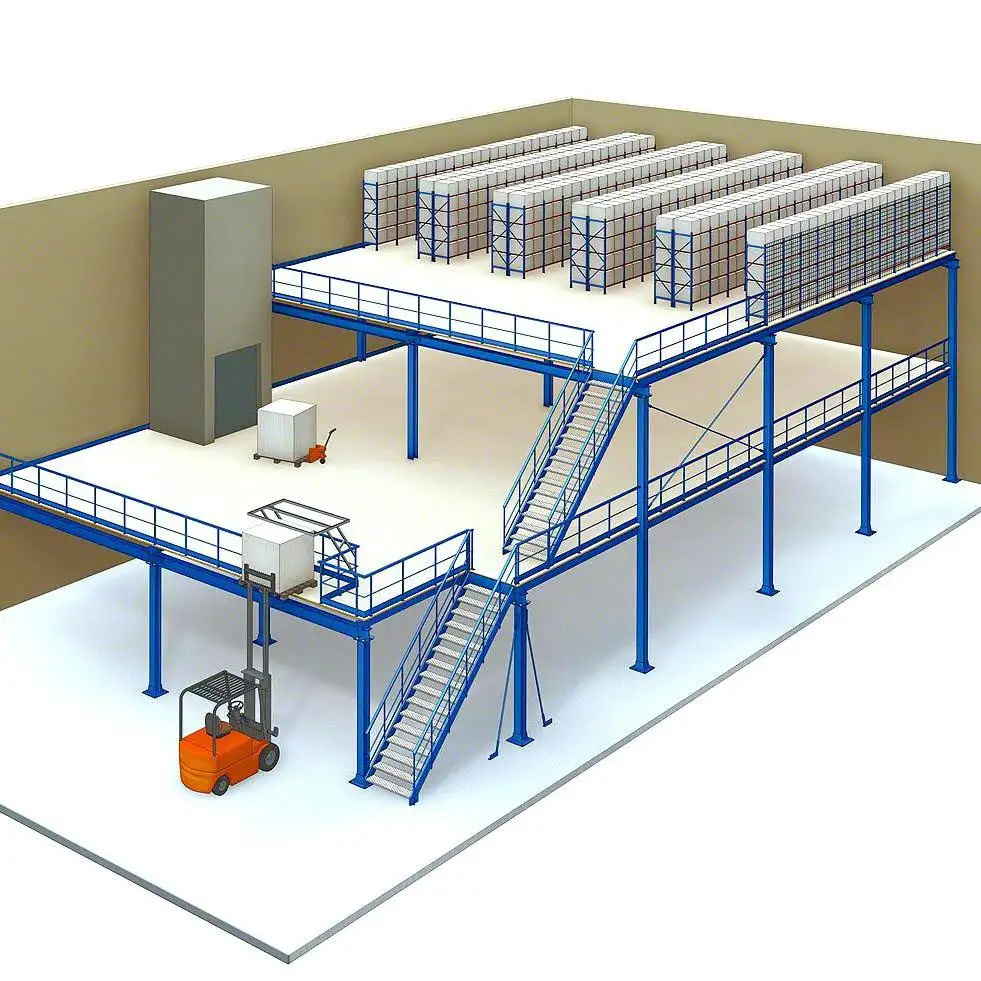

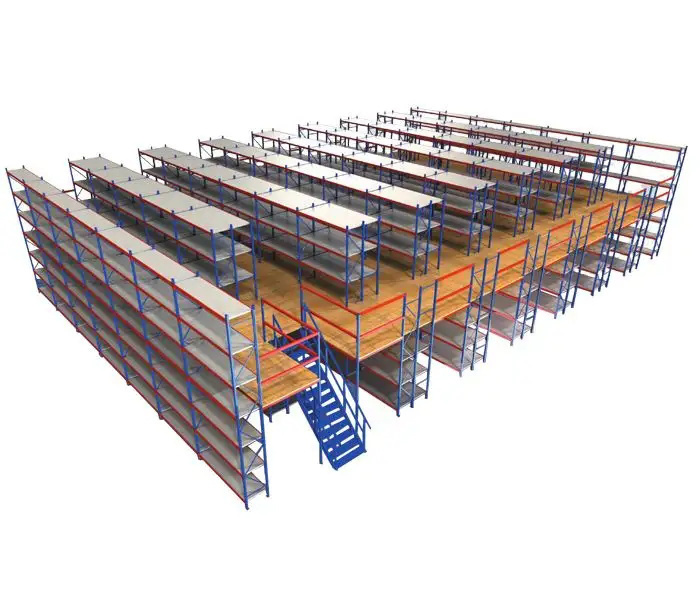

In today's land-scarce warehousing environments, maximizing vertical space utilization has become a core strategy for cost reduction and efficiency improvement. Mezzanine racking, as an innovative three-dimensional storage solution, constructs multi-level operating platforms on existing floors or shelving systems, enabling vertical expansion of storage space while significantly increasing storage density and operational efficiency.

I. Technical Features: Engineering Intelligence for Spatial Reconstruction

1.Modular Flexible Structure

Utilizes fully assembled steel frames with bolted connections for columns, beams, and decks (cold-rolled steel plates/steel grating), enabling rapid disassembly and reconfiguration without welding. This design adapts flexibly to irregular spaces (e.g., column zones, atypical layouts), maximizing unused vertical height.

2.High-Load Stability Design

Supported by medium or heavy-duty racking skeletons, with deck load capacity reaching 500-1000kg/㎡. I-beam reinforcement and scientific load calculations ensure stable operation within 6-meter heights, accommodating diverse cargo weights.

3.Human-Machine Collaborative System

Level heights (2.2-2.7m) and top platform clearance (≤4m) balance manual access and mechanized operations:

● Vertical Transport: Forklifts, hydraulic lifts, or freight elevators handle cross-floor movement

● Horizontal Transfer: Light carts/hydraulic pallet trucks achieve "last-ten-meter" precision positioning

● Efficiency Boost: Integrated tractors or electric hoists increase transfer efficiency by 40%+

II. Core Value: Multi-Scenario Efficiency Solutions

1.Space Utilization Multiplier

Converts single-level areas into 2-3 tiered storage zones, increasing density by 50%-100%—ideal for high-rent urban areas or legacy warehouse retrofits.

2.Cross-Industry Adaptability

Demonstrates exceptional performance across sectors:

● E-commerce Logistics: Manages massive SKUs of small items; an East China warehouse case achieved 2.3x storage capacity and 35% faster picking

● Machinery Manufacturing: Centralizes tools/components; enables second-level production line material replenishment

● Cold Chain Storage: Preserves pharmaceuticals/food in temperature-controlled environments with 60% higher slot utilization

● Archival Management: Securely stores documents/books with 80%+ space efficiency

3.Multi-Functional Integration

Upper platforms flexibly serve as storage zones, light assembly lines, QC stations, or offices, enabling vertical integration of warehousing and production workflows.

III. Critical Implementation Standards

1.Safety Protection Systems

● ≥1.1m guardrails and anti-slip staircases on all levels

● Emergency lighting, fire sprinklers, and climate control

● Galvanized steel grating decks required for cold environments

2.Scientific Load Design

Dynamic structural adjustments per cargo type:

● Cartons: 1.5mm cold-rolled steel plates

● Metal parts: 3mm I-beam frames with reinforced crossbeams

● Mandatory safety margins for equipment and personnel

3.Intelligent Flow Planning

● Simulate U-shaped/loop pathways via planning software

● Separate forklift zones from manual picking areas

● Strict aisle-width matching for equipment turning radius

IV. Future Evolution Trends

1.Smart Technology Integration

Combines WMS, RFID, and AGVs for auto-location allocation and ≥99.9% inventory accuracy.

2.Sustainable Flexible Design

● Recyclable aluminum frames with eco-coatings

● Modular expansion during peak demand (e.g., 3x capacity for e-commerce sales events)

● Motion-sensing LEDs cut energy use by 30%

3.Ecosystem Synergy

Complements AS/RS to build multi-tiered smart warehouse networks for resilient supply chains.

Conclusion

Mezzanine racking delivers economically efficient warehouse upgrades through "spatial reinvention." Its value extends beyond vertical expansion to redefining storage operations via modular engineering, human-machine collaboration, and intelligent systems. As IoT and advanced materials converge, this traditional solution gains renewed vitality, continuously empowering global supply chain optimization. Enterprises must align technical planning with cargo profiles, workflows, and safety protocols to fully unlock the strategic potential of three-dimensional storage systems.

Key words:

Related Solutions

Related Cases

undefined

Related Products

TEL: +86-13091097380

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China8

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2020 hebei walker metal products co., ltd

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home