-

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogIn recent years, Haigelis has designed, manufactured, and installed a series of warehousing and logistics projects for well-known domestic companies such as Sinopec, PetroChina, Coca-Cola, Yihai Kerry, Alibaba Cainiao Logistics, Junlebao, Jinmailang, North China Pharmaceutical, Lucky Film, YTO Express, and Inner Mongolia Xinhua Publishing and Distribution Group.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

HEGERLS Integrated Racking System: Reshaping Warehouse Space Value, Driving Intelligent Logistics Upgrade

Classification:

Industry Info

Release time:

2025-07-02

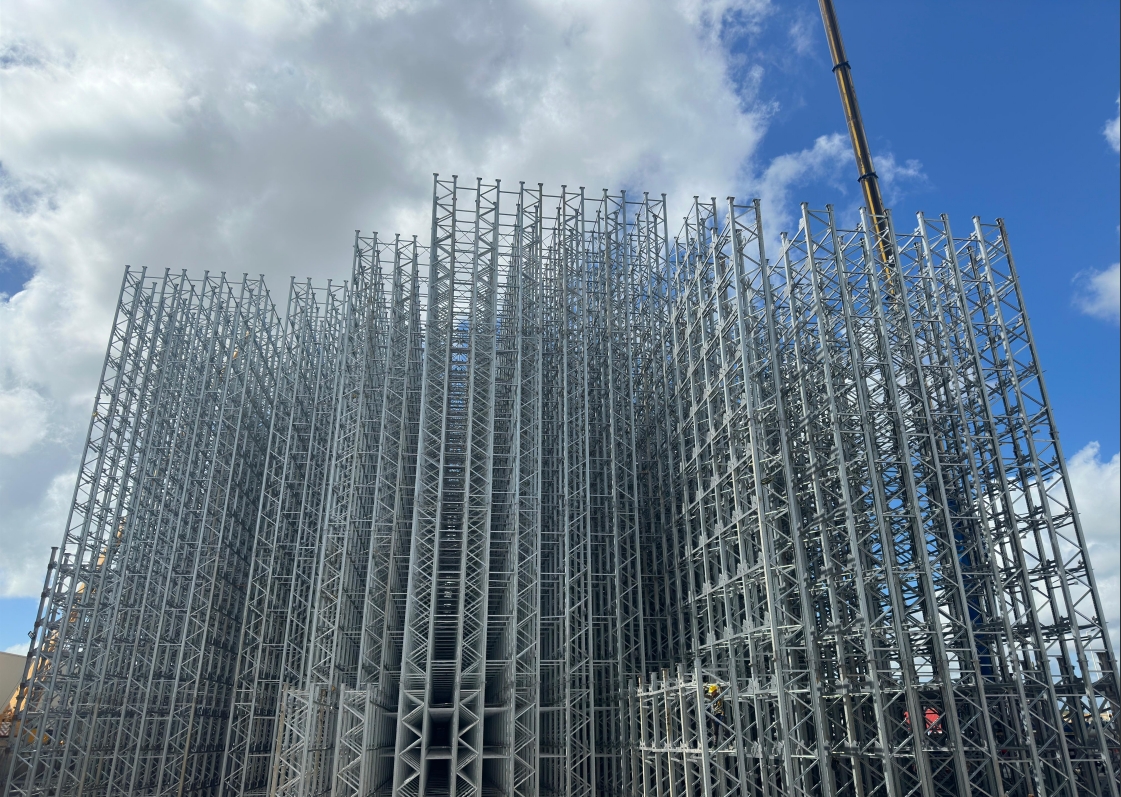

Amid the dual pressures of rising land costs and soaring demand for logistics efficiency, the modern warehousing industry is undergoing profound transformation. As a benchmark enterprise in the warehousing and logistics equipment sector in North China, Hebei Woke Metal Products Co., Ltd. (with its proprietary brand "HEGERLS") has provided a groundbreaking space utilization solution for global enterprises through its innovative integrated racking system. This system, which combines architectural structure with storage functionality, not only redefines the value boundaries of warehousing space but also emerges as a critical infrastructure driving the transformation of intelligent manufacturing and green logistics.

I. Technological Innovation: A Structural Revolution from Racks to Architecture

The core breakthrough of the integrated racking system lies in its "racks-as-architecture" design philosophy. Traditional warehouse buildings allocate 5%-15% of cubic space to independent load-bearing columns, whereas HEGERLS utilizes high-strength cold-formed thin-walled steel frameworks, enabling racking columns to directly bear architectural loads and achieving over 30% improvement in space utilization. Take a tire manufacturer's project as an example: a 40-meter-high integrated warehouse doubled storage capacity compared to conventional warehouses on the same footprint while reducing land costs per unit by 40%.

The system's technological advantages manifest in three aspects:

- ● Structural Optimization: Modular design allows adjustable beam levels and aisle widths, supporting seamless integration with automated equipment such as AGVs and four-way shuttles.

- ● Material Innovation: Q235B steel construction with hot-dip galvanizing and electrostatic coating ensures corrosion resistance exceeding 25 years, with maintenance costs merely one-third of traditional racking.

- ● Safety Enhancement: Finite element analysis optimizes joint designs, enabling resistance to Category 12 typhoons and Magnitude 8 earthquakes. Field tests at an auto parts warehouse controlled rack sway within ±15mm under extreme wind conditions.

II. Scenario Empowerment: Cross-Industry Solution Implementation

HEGERLS integrated racking has deeply penetrated multiple industrial sectors, forming differentiated solutions:

- ● High-Density Storage: In the food and beverage industry, integration with AS/RS stacker systems enables automated pallet handling, achieving 300 pallets/hour picking efficiency and 65% labor cost reduction.

- ● Cold Chain Optimization: A cold logistics center adopting dual-layer polyurethane insulated panels with integrated racking reduced energy consumption by 18% at -25°C while mitigating cold bridge effects by 90%.

- ● Flexible Manufacturing: Custom scalable racking systems for equipment manufacturers support 5-year capacity growth projections, avoiding wasteful warehouse reconstruction.

Particularly in land-scarce regions like Eastern and Southern China, integrated racking has become the preferred solution for e-commerce logistics centers. The Cainiao Logistics Jiangmen Base achieved 220% volumetric efficiency improvement and 40% faster throughput after adopting the system.

III. Intelligent Integration: Building the Future of Warehousing Ecosystems

As intelligent manufacturing infrastructure, HEGERLS integrated racking deeply integrates IoT and big data technologies:

- ● Digital Twin: Embedded RFID sensors provide real-time structural stress data, enabling WMS integration with <0.01% inventory error rates.

- ● Energy Management: Optional photovoltaic roof integration generates 1.2 million kWh annually for a new energy enterprise, meeting 30% of its power demand.

- ● Predictive Maintenance: AI-driven historical data analysis provides 3-month advanced warnings of structural fatigue risks, reducing equipment failure rates by 80%.

IV. Industry Leadership: Standardization Meets Customization

Facing homogenized competition in the racking sector, Hebei Walker builds核心竞争力 through "technology-driven innovation + quality commitment":

- ● R&D Strength: Over 50 patents and participation in drafting 3 national standards including Warehouse Racking Safety Specifications.

- ● Global Reach: Products exported to 110+ countries/regions, serving Fortune 500 clients including Sinopec, Coca-Cola, and YTO Express.

- ● Service Network: Regional service centers in Bangkok, Thailand and Kunshan, Jiangsu provide 72-hour rapid response.

- Conclusion: Spatial Revolution Driving Industrial Upgrades

Driven by "dual carbon" goals and intelligent manufacturing trends, integrated racking has evolved from innovative experiment to industry standard. With 29 years of technical accumulation, Hebei Woke Metal Products Co., Ltd. is redefining warehousing space logic—transforming it from mere storage venues into strategic assets for enterprises seeking cost reduction, efficiency gains, and green transformation. Choosing HEGERLS integrated racking means embracing a more efficient, intelligent, and sustainable logistics future.

Key words:

Related Cases

undefined

Related Products

MOBILE: +86 133 1595 3337

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China8

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2025 Hebei Woke Metal Products Co., ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home