-

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogIn recent years, Haigelis has designed, manufactured, and installed a series of warehousing and logistics projects for well-known domestic companies such as Sinopec, PetroChina, Coca-Cola, Yihai Kerry, Alibaba Cainiao Logistics, Junlebao, Jinmailang, North China Pharmaceutical, Lucky Film, YTO Express, and Inner Mongolia Xinhua Publishing and Distribution Group.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

Extra long cargo? Cantilever shelving: It can fit and hold more securely!

Classification:

FAQ

Release time:

2025-08-18

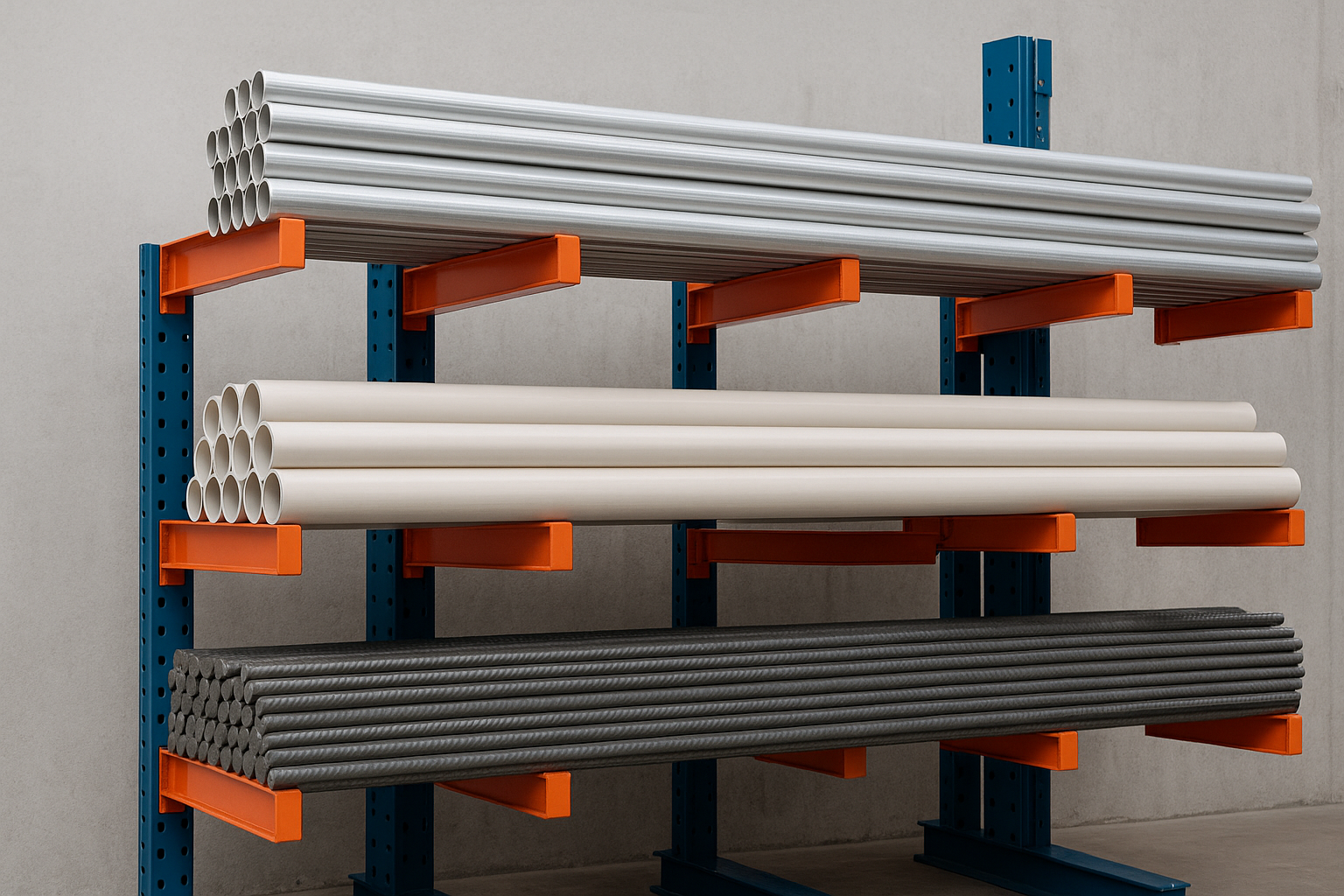

In modern warehousing and logistics systems, efficiently and safely storing irregular or oversized materials has always been a challenge. Cantilever shelves, with their unique design concept, have become the preferred solution for solving such storage problems.

1. Core structure: Simple but not simplistic

The core of cantilever shelves lies in the clever combination of "columns+cantilevers":

● Column: As the load-bearing skeleton of the entire system, it is usually made of heavy-duty steel to ensure stable support in the vertical direction.

● Cantilever: a key component that extends horizontally and is securely fixed to a column using high-strength connectors such as bolts or clamps. Its length, quantity, and layer height can be flexibly adjusted according to actual storage needs.

● Single/double-sided design: The cantilever can be installed only on one side of the column (single-sided), suitable for areas near walls; Or symmetrically installed on both sides of the column (double-sided) to form a central storage channel and improve warehouse space utilization.

2. Classified by "power": matching different carrying requirements

Cantilever shelves are not uniform, and their load-bearing capacity is an important distinguishing dimension:

● Lightweight type: Single arm load-bearing capacity is usually below 300kg, suitable for storing lightweight long boards and decorative materials in building materials markets, home furnishing stores, etc.

● Medium weight type: A single arm can carry about 300kg to 800kg, commonly used in pipe factories and profile processing workshops to store medium-sized metal pipes and plastic profiles.

● Weight type: A single arm can carry over 800kg or even several tons, designed specifically for industrial heavy materials such as heavy steel beams and large robotic arms.

3. Core Advantage: Why is it highly favored?

● Excellent load stability: The cantilever structure combined with heavy-duty columns forms a stable triangular mechanical support, especially adept at dealing with the leverage force generated by long materials, avoiding front-end sagging deformation.

● Efficient space utilization: The cantilever front end has no vertical obstacles, and materials can be directly accessed from the side (such as using a forklift), especially suitable for warehouses with limited floor height. The double-sided design maximizes the utilization of central space.

● Excellent material adaptability: Whether it's pipes over ten meters long, irregularly shaped profiles, large boards, or bundled textiles, the open space between the cantilevers can easily accommodate them without the need for additional shelf boards.

● Flexible scalability: The cantilever length, floor height, and quantity can be customized and adjusted as needed to adapt to business growth or changes in storage items.

4. Typical application scenarios

Cantilever shelves are widely used in industries that require storage of long, irregular, or bulky items:

● Building materials and profiles industry: wood, aluminum profiles, PVC pipes, steel bars, stone slabs.

● Metal processing and manufacturing industry: metal pipes, bars, steel coils, and large mechanical components.

● Furniture and Home Furnishing Industry: Panels, Carpet Rolls, Large Furniture Components.

● Warehousing and logistics: plastic pipes, rolled textiles, and ultra long packaging materials.

5. Key points of design and selection

●Accurate load assessment: Clarifying the individual weight, length, and distribution of stored items is the basis for selecting light, medium, and heavy loads and determining cantilever specifications.

● Reasonable space planning: Combine warehouse clearance height, column spacing, and channel width (to ensure forklift operation space) for layout design.

● Pay attention to safety details: consider adding diagonal braces and rear braces to enhance overall stability; Install baffles or protective covers at the end of the cantilever to prevent goods from slipping and protect the shelves.

● Professional installation and maintenance: Installation and debugging must be carried out by professional personnel, and bolt tightness, cantilever levelness, and structural integrity must be checked regularly. Overloading is strictly prohibited.

Conclusion

Cantilever shelves, with their simple yet powerful mechanical structure, provide a safe and efficient storage solution for long, irregular, and heavy materials. Its excellent carrying capacity, spatial adaptability, and convenient access make it an indispensable infrastructure in many industrial and commercial warehousing scenarios. Scientific selection and standardized use can maximize its efficiency and provide solid support for logistics operations.

Key words:

Previous:

Related Solutions

Related Cases

undefined

Related Products

MOBILE: +86 133 1595 3337

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China8

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2025 Hebei Woke Metal Products Co., ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home