-

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogProfessional articles, guides, and insights on warehouse racking and automated storage systems.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

Auto Parts Warehouse Solutions

Classification:

Application

Release time:

2020-10-22

HEGERLS: Efficient Storage for Automotive Components

The automotive parts industry requires warehouses that handle high SKU variety, precise inventory management, and safe handling of heavy and small components. From engines, transmissions, and suspension systems to small fasteners and electronic modules, warehouses must support organized storage, rapid picking, and streamlined distribution.

HEGERLS provides customized racking, shelving, and automated warehouse systems specifically designed for automotive parts storage, helping manufacturers, distributors, and aftermarket suppliers optimize space, reduce errors, and improve operational efficiency.

Challenges in Auto Parts Warehousing

High SKU Variety: Thousands of different components, from small bolts to large assemblies.

Space Optimization: Need for high-density storage without sacrificing accessibility.

Inventory Accuracy & Traceability: Essential for just-in-time manufacturing and aftermarket supply.

Weight & Size Variations: Items range from lightweight electronics to heavy engine blocks.

Fast Picking & Distribution: Timely supply for production lines and repair centers is critical.

HEGERLS Storage Solutions for Auto Parts

1. Selective Pallet Racking

Ideal for bulk parts, tires, and assemblies.

Adjustable beams support varying pallet sizes.

2. Flow Racking / FIFO Systems

Perfect for small, high-turnover components like screws, bearings, and electronics.

Ensures first-in, first-out rotation for consistent inventory flow.

3. Cantilever Racking

Designed for long parts such as drive shafts, bumpers, and exhaust pipes.

Open-front access for easy handling.

4. Mezzanine Platforms & Shelving

Expands vertical space for small components, kits, and accessories.

Supports multi-level picking operations.

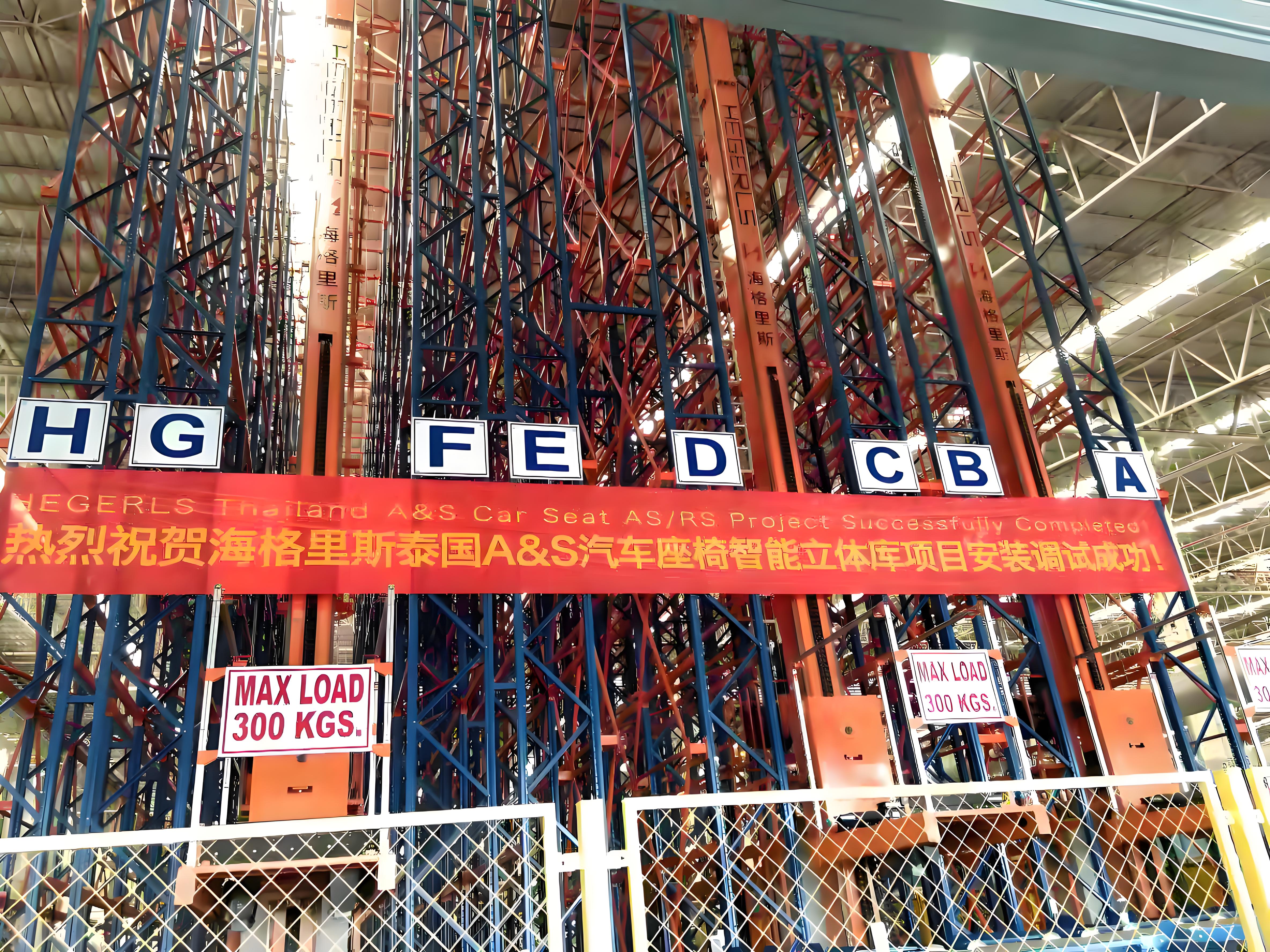

5. Automated Shuttle & AS/RS Systems

High-density automation for mixed small and medium-sized auto parts.

Reduces errors, speeds up retrieval, and improves inventory accuracy.

Key Benefits of HEGERLS for Auto Parts Warehouses

High-Density & Organized Storage: Efficient use of space for mixed SKU warehouses.

Inventory Accuracy: Supports JIT production and aftermarket logistics.

Flexibility & Customization: Tailored solutions for components of varying size, weight, and turnover.

Automation Ready: Shuttle, AS/RS, and conveyor integration improves speed and efficiency.

Global Expertise: Implemented for automotive manufacturers and distributors in Asia, Europe, and the Americas.

Our Implementation Process

At HEGERLS, we don’t just provide racking systems—we deliver end-to-end warehouse solutions through a structured implementation approach:

Warehouse Analysis – Comprehensive assessment of space, workflow, and inventory needs.

Solution Design – Custom layout planning and equipment selection for maximum efficiency.

Simulation & Validation – Operational modeling to ensure performance before installation.

Professional Installation – Expert assembly with minimal disruption to operations.

Comprehensive Training – Staff education on equipment operation and safety.

Ongoing Support – Continuous maintenance, upgrades, and optimization for long-term success.

Application Examples

Automotive Component Distribution Centers – Pallet racking for engines, transmissions, and chassis parts.

Aftermarket Spare Parts Warehouses – Flow racking and shelving for small parts and accessories.

Assembly Line Support Warehouses – Automated systems for timely supply to production lines.

Long Component Storage – Cantilever racking for exhaust pipes, drive shafts, and body panels.

Why Choose HEGERLS for Auto Parts Warehousing

Nearly 30 Years of Industrial and Automotive Warehouse Experience

Patented Shuttle & Heavy-Duty Racking Systems

Custom Layouts for High SKU Variety

Global Projects with Automotive Manufacturers and Distributors

Looking to optimize your auto parts warehouse?

Contact HEGERLS today for a custom warehouse solution tailored to automotive components.

Key words:

Related Solutions

Related Cases

Hebei Dingzhou Garrison Reserve Grain Depot Shuttle Car Shelf System Storage Project

Sweden's SWEDMART company's crossbeam warehouse project

Related Products

MOBILE: +86 133 1595 3337

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2025 Hebei Woke Metal Products Co., ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home