Pallet Racking

Classification:

Application:

Key Advantages of Warehouse Pallet Racking

Space Optimization: Pallet racks let you build vertically, turning unused ceiling space into productive storage. This improves capacity without expanding floor area.

Full Accessibility & Selectivity: In many configurations (e.g. selective racking), every pallet is directly accessible at all times, eliminating the need to move other pallets to reach one.

Improved Inventory Control & Flow: Organized rack bays, labeling, and tiered storage help streamline picking, reduce search time, and enhance stock visibility.

Safety & Product Protection: Elevating goods off the floor reduces damage from forklifts, water, or accidental impact. Racking systems are engineered for load limits and can incorporate safeguards (back mesh, column protectors, safety pins).

Scalability & Flexibility: As inventory or SKU mix changes, pallet racks can be reconfigured, expanded, or adapted to new layouts.

Return on Investment: A well-engineered racking system enhances property value and reduces long-term operational costs (labor, storage inefficiencies).

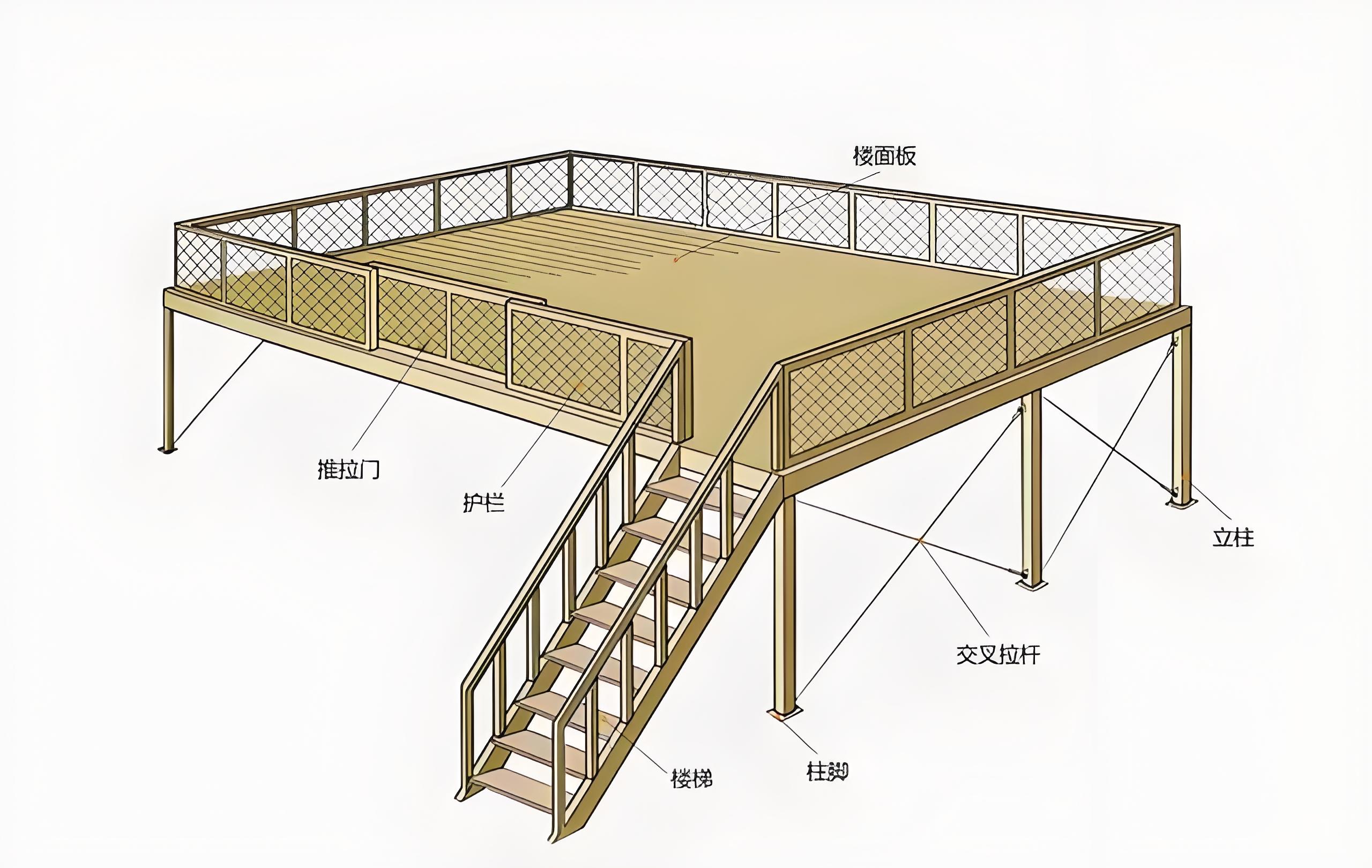

Structure & Components of Common Pallet Racking Systems

Upright Frames / Columns: Load-bearing vertical supports.

Horizontal Beams / Crossbeams: Connect uprights to create shelf levels.

Decking / Load Platforms: Steel plates, wire mesh, or wood boards that support pallets.

Bracing & Rigidity Elements: Diagonal, horizontal bracing for stability under load.

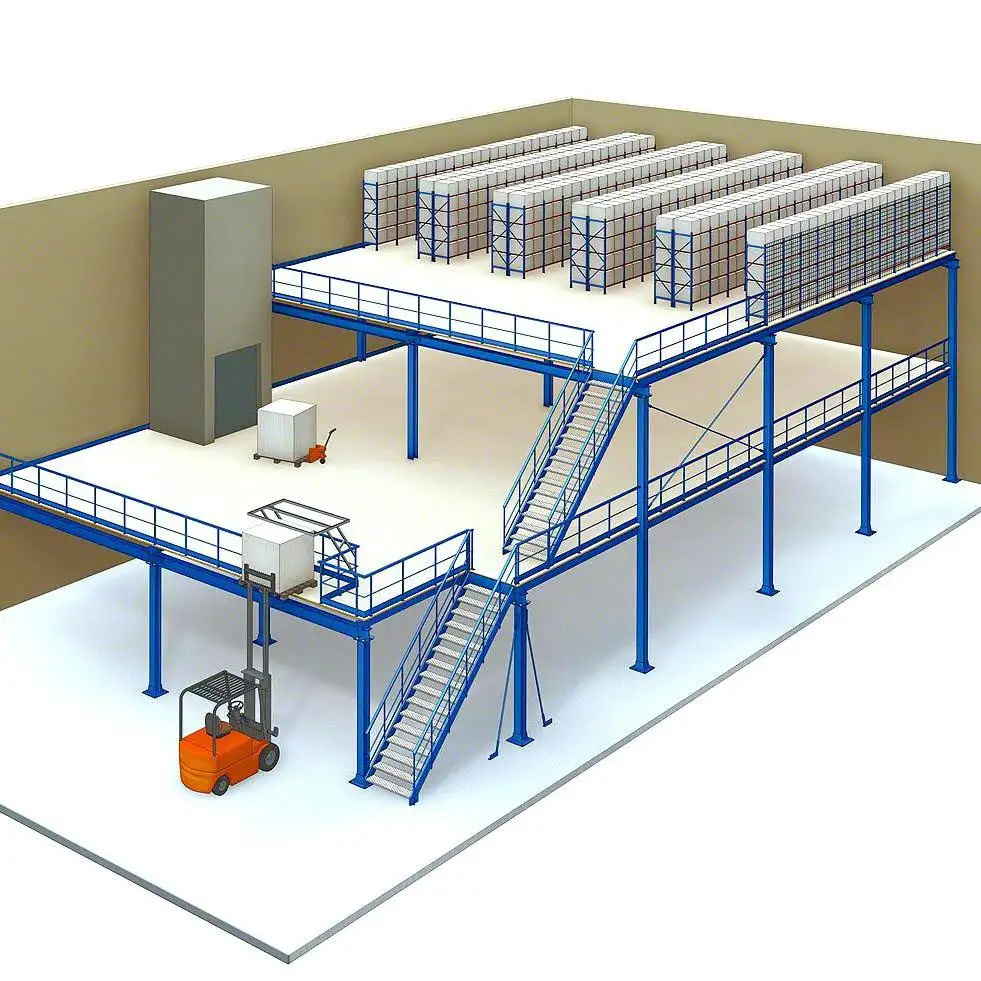

Safety & Access Accessories: Safe pins, locking bars, column protectors; Back stops, wire mesh back panels; Guardrails, walkways (for mezzanine-supported configurations)

Anchoring / Base Plates: Secure rack to floor for stability, seismic safety.

Typical Applications

Pallet racking is broadly applicable, such as:

- Distribution centers / 3PL warehouses

- Manufacturing storage for raw materials or finished goods

- Cold storage or frozen warehouses

- Retail backrooms or bulk storage

- Parts storage in automotive / electronics industries

- Any facility requiring organized pallet-level inventory

Customization & Configuration Options

| Parameter | Options / Considerations |

|---|---|

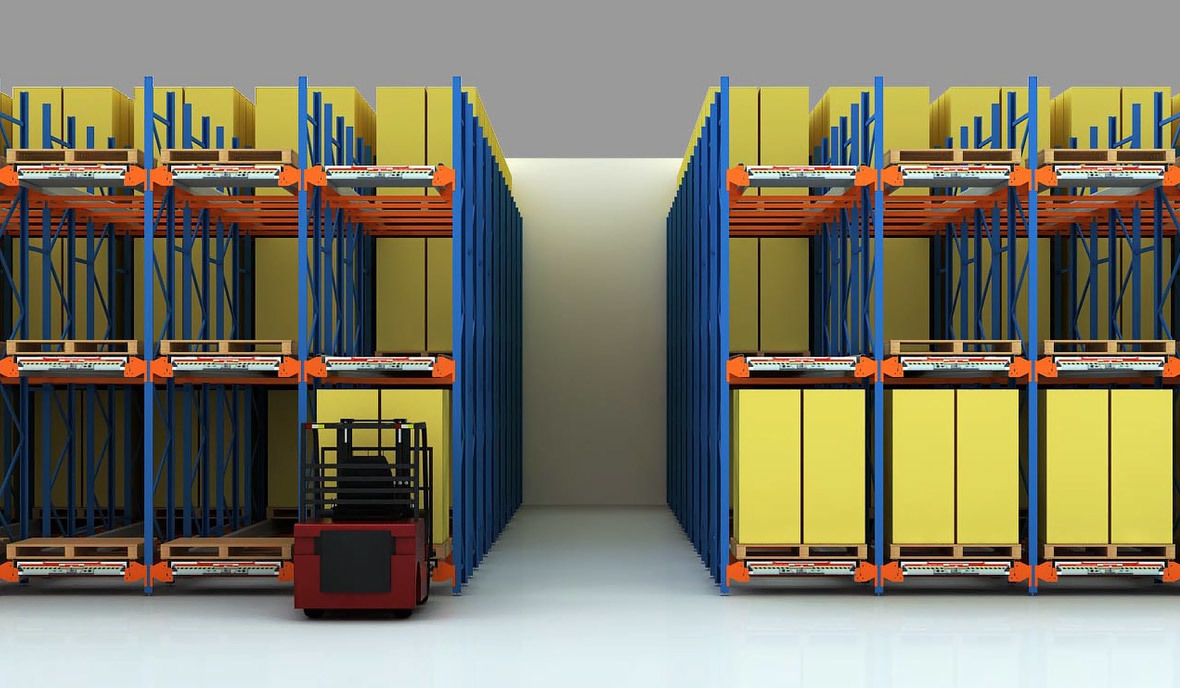

| Depth | Single-deep, double-deep, drive-in, drive-through |

| Height | Based on ceiling clearance, forklift reach |

| Beam lengths | Custom to bay widths |

| Load capacity | Engineered per pallet weight & usage |

| Decking style | Steel, wire mesh, wood infill |

| Safety features | Mesh backing, safety rails, seismic bracing |

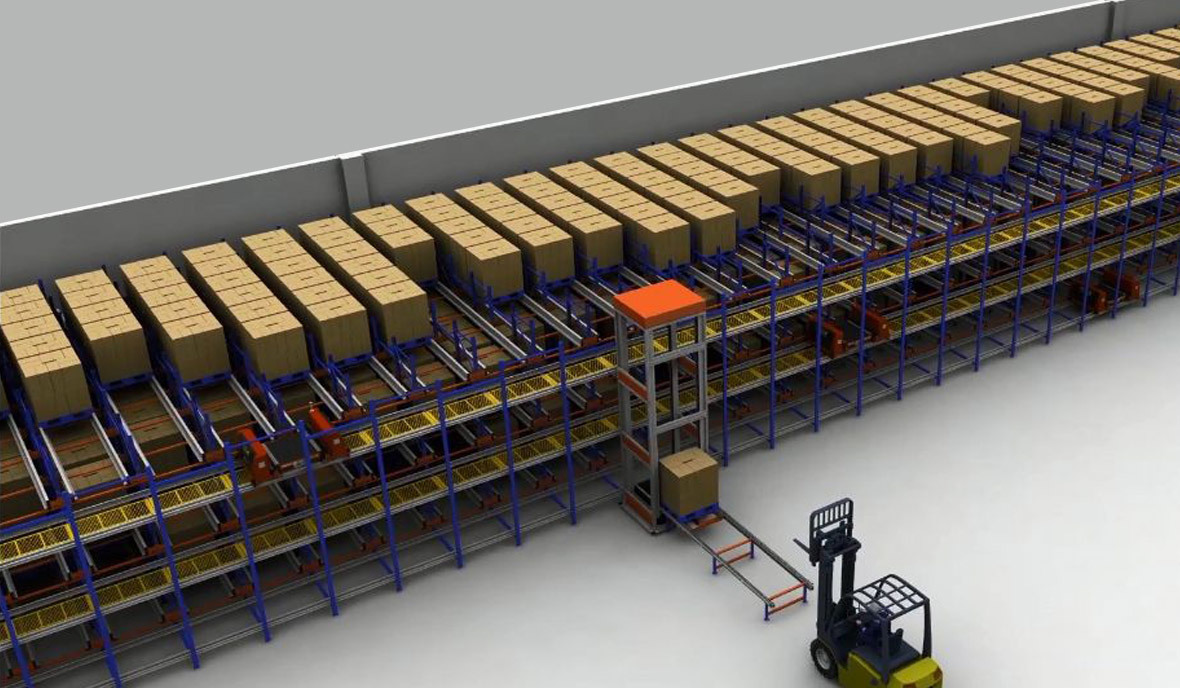

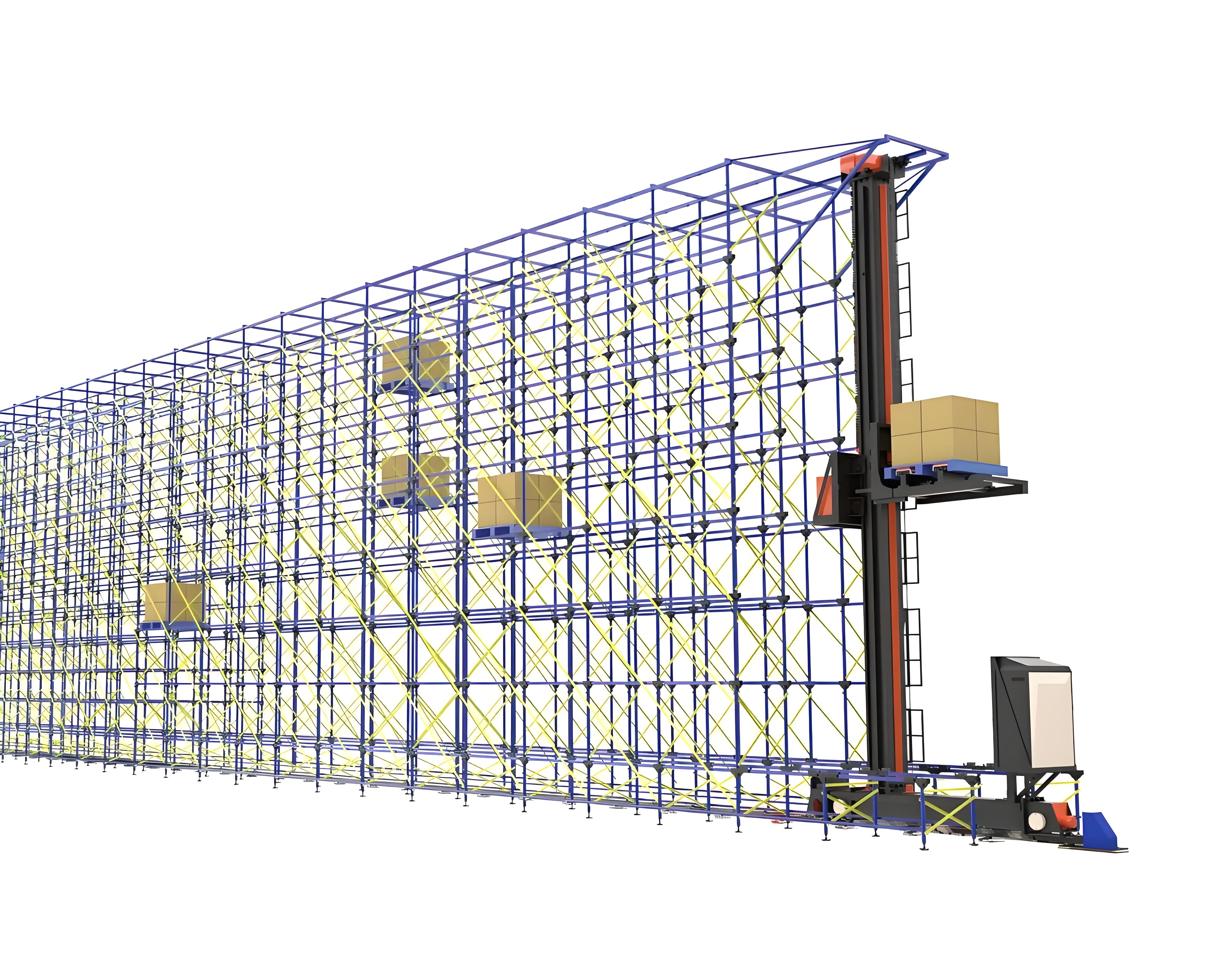

| Integration | Combine with mezzanines, conveyors, AS/RS |

We can provide custom pallet racking solutions: full layout design, load calculations, and tailored configurations to match your warehouse’s architecture and workflow.

Safety & Best Practices

- Ensure rack is installed on a flat, level floor, with anchor bolts.

- Adhere to rated loads per beam / level and avoid overloading.

- Use column protectors, guardrails, and back mesh panels to prevent accidents.

- Inspect components regularly; replace bent or damaged parts immediately.

- Train forklift operators to enter aisles and place pallets properly.

- Maintain aisle clearances and avoid staging pallets in rack aisles.

Why Choose HEGERLS Pallet Racking System?

- Boost vertical storage capacity and optimize floor space.

- Custom-fit solutions that adapt to your warehouse layout and operations.

- Cost-efficient and reliable for long-term use.

- Ideal for environments where forklift-driven, pallet-centric workflows dominate.

Ready to transform your warehouse storage capacity with efficient, reliable pallet racking? Let HEGERLS design a storage solution that perfectly fits your space, inventory, and workflow.

Contact us now for a free 3D layout & quote.

Key words:

Pallet racking

Industrial Storage Systems

Heavy Duty Storage Racks

Heavy Duty Shelving

Warehouse Racking Systems

Previous Page:

Next page:

Related Solutions

Shuttle + Forklift (AGV forklift) Intelligent Intensive Storage System and Solutions

Shuttle + stacker crane intelligent dense storage system and solution

Shuttle car & carrier + lift intelligent dense storage system and solution

Related Products

Product free consultation

HEGERLS has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955