-

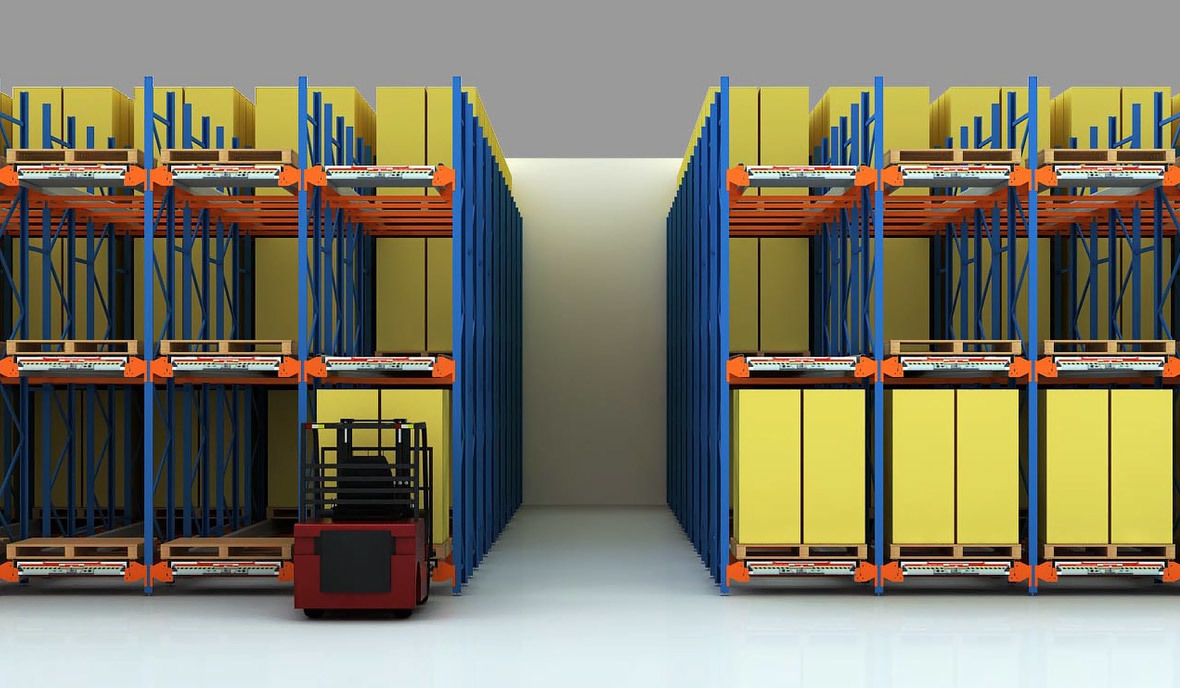

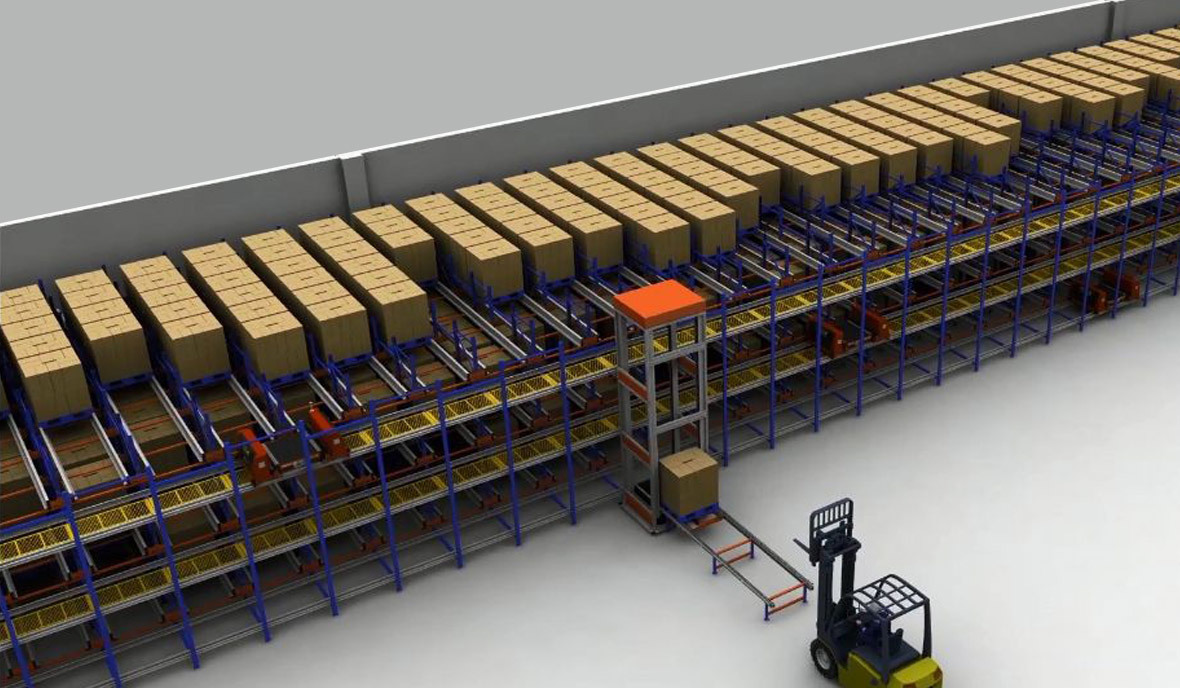

SOLUTIONSIn recent years, “Hegerls" HD shuttle storage system have improved, upgraded, more intelligent, flexible, and more systematic, which can meet the different needs of customers in various industries.

SERVICE

SERVICE -

-

R & DObtained more than ten national patents for automated logistics warehousing equipment such as shuttle cars, stackers, and mobile shelves, awarded SGS, BV, and TUV international product quality inspection agency certificates, as well as the "Quality, Environment, Health" ISO three major system certification certificates.

SERVICE

SERVICE -

PROJECTSAfter Haigelis entered the international market in 2011, it exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its efforts in the research and development of automated warehousing equipment.

SERVICE

SERVICE -

BlogProfessional articles, guides, and insights on warehouse racking and automated storage systems.

SERVICE

SERVICE -

HEGERLSIt's developed over 20 years, our company has become a one-stop integrated service provider of warehousing and logistics, integrating warehousing and logistics project design...

SERVICE

SERVICE

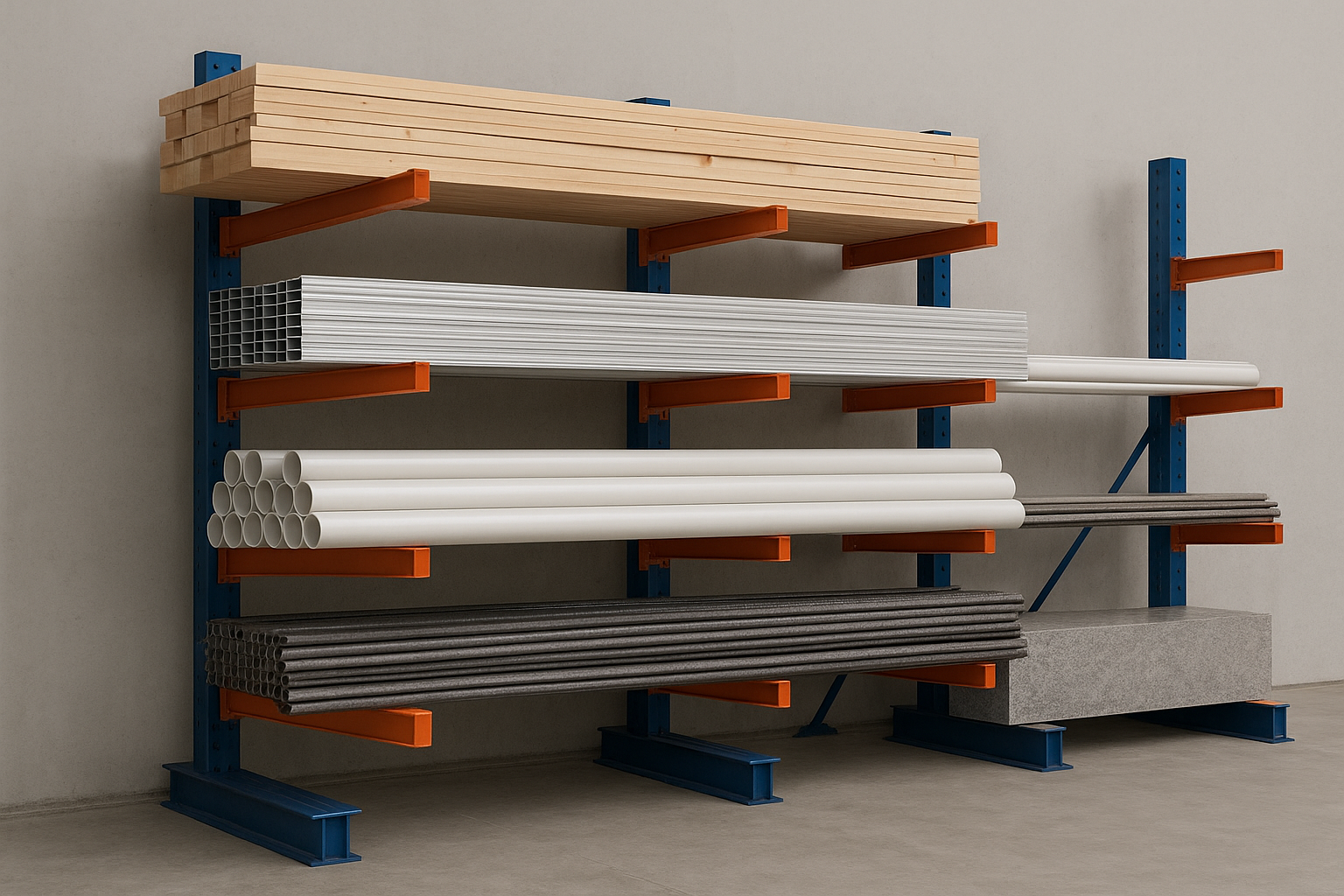

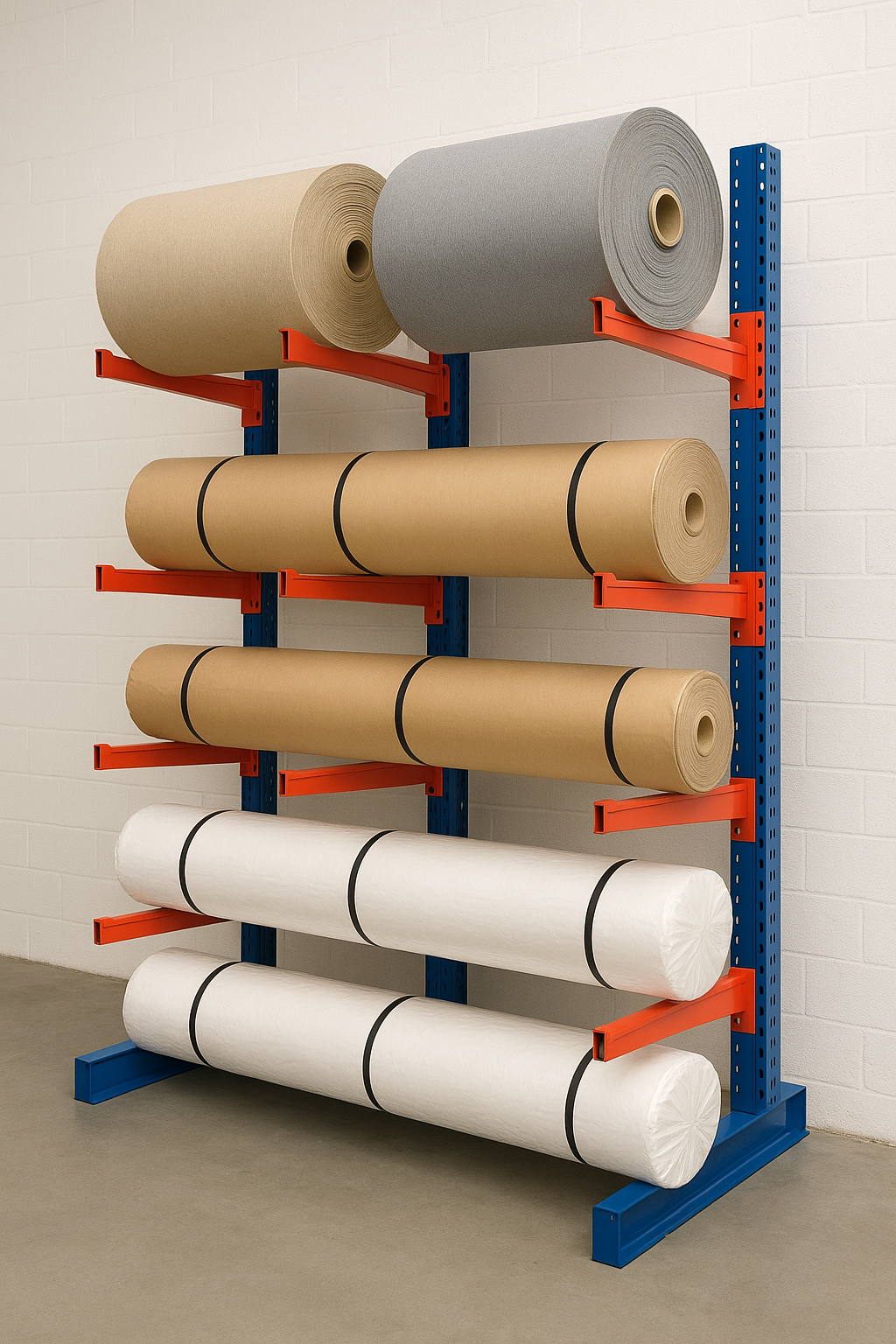

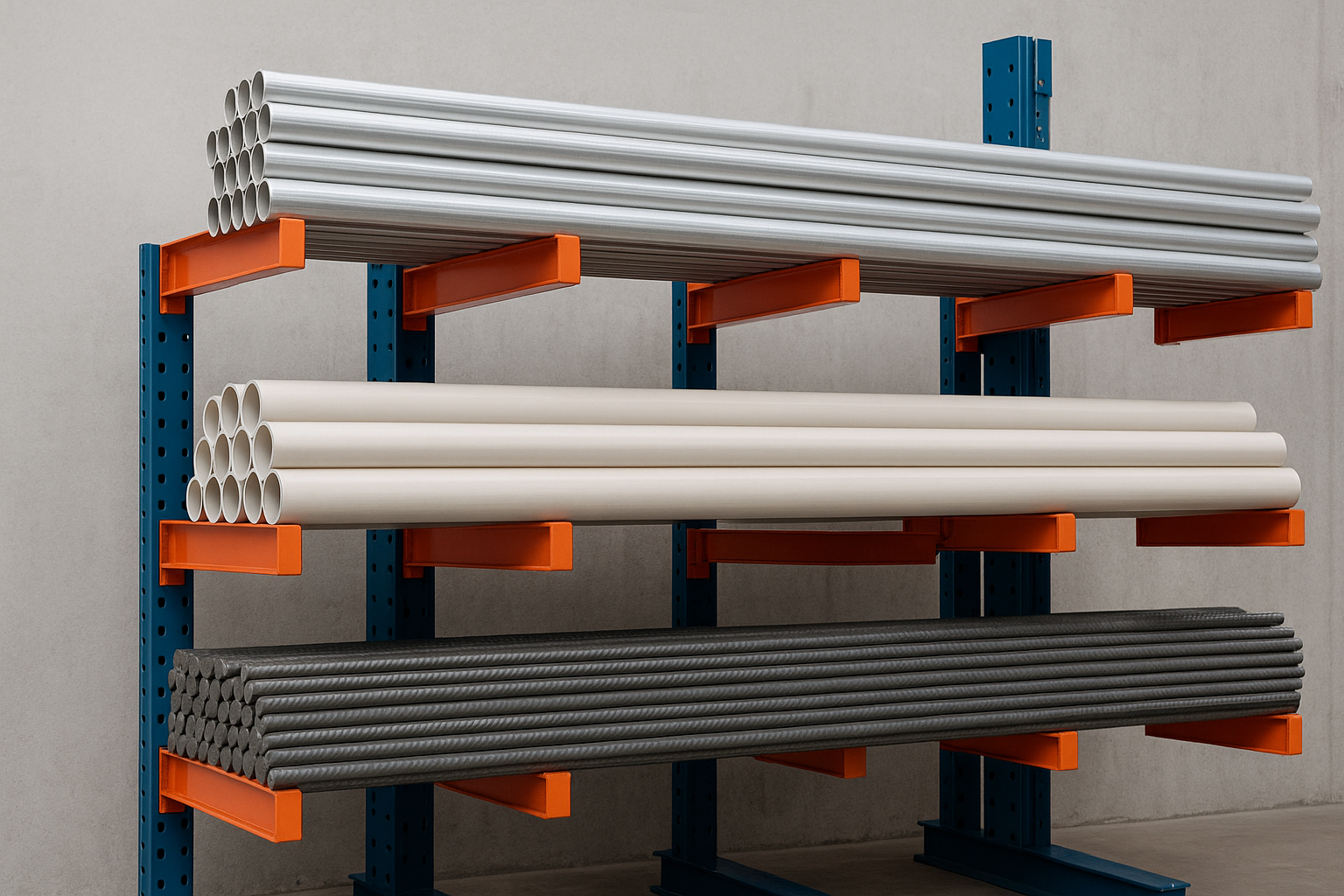

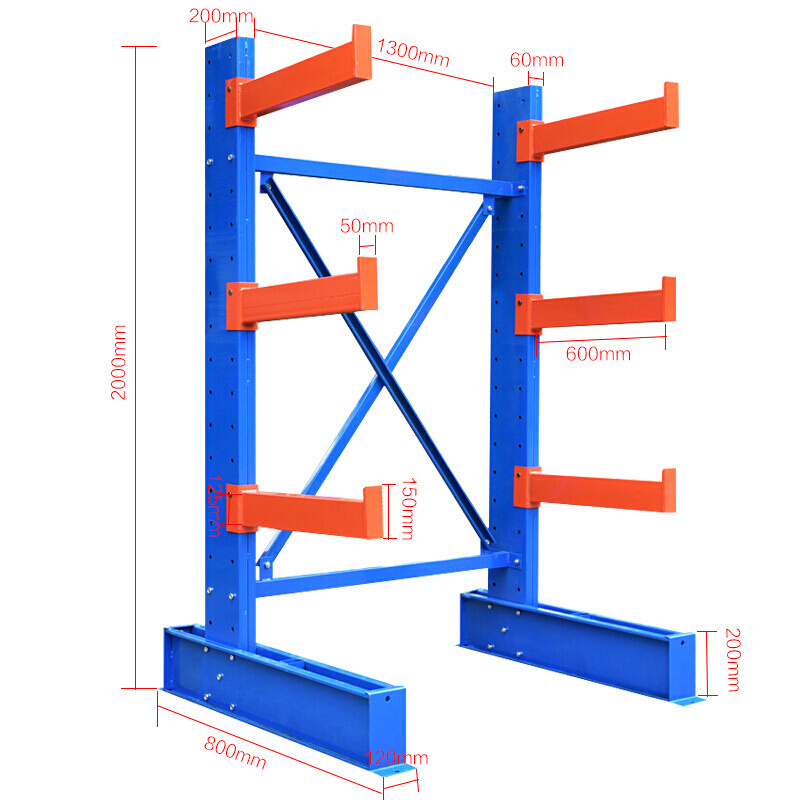

Cantilever racking

Classification:

Application:

Key Features & Benefits of Cantilever Racking

Optimal for oversized loads: The arms support long or awkwardly shaped materials which standard racking systems struggle with.

Open-front design: Without a front support column, accessing materials is faster and safer.

Flexible configuration: The arms are adjustable and the system can be configured single-sided (against a wall) or double-sided (in the middle of a bay) to maximize space.

High vertical usage: Makes better use of height by elevating long goods and freeing up valuable floor space.

Indoor & outdoor capable: With appropriate weatherproof finishes (e.g., galvanized steel or powder coat), it can be used outdoors as well.

Components & Structure

Vertical Columns / Uprights – The main back support which the arms extend from.

Cantilever Arms – Horizontal load-bearing arms which hold the goods; length and number of arms customized based on load size.

Base & Bracing – Ensures stability, especially for longer arms and higher loads; includes horizontal/diagonal bracing for safe load support.

Optional Decking & Accessories – For some applications, decking or end-stops may be applied to the arms to prevent roll-off, protect stored items, or support load bundles.

Typical Applications

The system is especially suited to:

- Lumber yards, timber storage and wood panel distribution

- Steel bars, pipes, tubing, sheet metal and building materials

- Furniture warehouses, carpet rolls, window frames, door stocks

- Outdoor storage yards or overflow zones with long load items

- Manufacturing and fabrication facilities needing heavy, irregular goods storage

Specification Options

| Parameter | Typical Options / Range |

|---|---|

| Arm length | Customized (depends on load length) |

| Load capacity per arm | Designed per material and usage |

| Configuration | Single-sided (wall) or double-sided (two way) |

| Finish | Powder coated / galvanized for outdoor use |

| Layout depth | Matching the forklift access width & load size |

| Expansion / modularity | Can add more uprights/arms as inventory grows |

Why Choose HEGERLS Cantilever Racking?

- We have years of experience designing specialist racking systems for long goods—ensuring safe, efficient storage and retrieval.

- Custom design support: We provide layout, arm specification, load calculation & finish selection to match your product profile.

- Quality manufacturing: Heavy-duty steel, precision fabrication, durable finishes; built for demanding storage environments.

- Flexible service: Whether indoor or outdoor, new build or retrofit, we handle the structural details for your long-load storage needs.

If your warehouse handles long or bulky items stacking on the floor, cluttering aisles or obstructing operations, then our Cantilever Racking system may be the solution you need. Contact us today for a free consultation and quote, and let’s design your ideal long-item storage bay.

Key words:

Industrial Storage Systems

Heavy Duty Storage Racks

Heavy Duty Shelving

Warehouse Racking Systems

Previous Page:

Next page:

Related Solutions

Shuttle + Forklift (AGV forklift) Intelligent Intensive Storage System and Solutions

Shuttle + stacker crane intelligent dense storage system and solution

Shuttle car & carrier + lift intelligent dense storage system and solution

Related Products

Product free consultation

HEGERLS has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955

MOBILE: +86 133 1595 3337

E-mails: hgls-wm@hbgysw.com

Office: Room 1118, Building No.6, Tatan Mall, Tatong Street, Shijiazhuang, China

Production base: 68 Shidai Road,Xinhe Industrial Park,Hebei Province

Website: https://www.woke-hercules.com

All rights reserved©2025 Hebei Woke Metal Products Co., ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home