Mobile Racking

Classification:

Application:

Key Features & Advantages of Mobile Racking Storage System

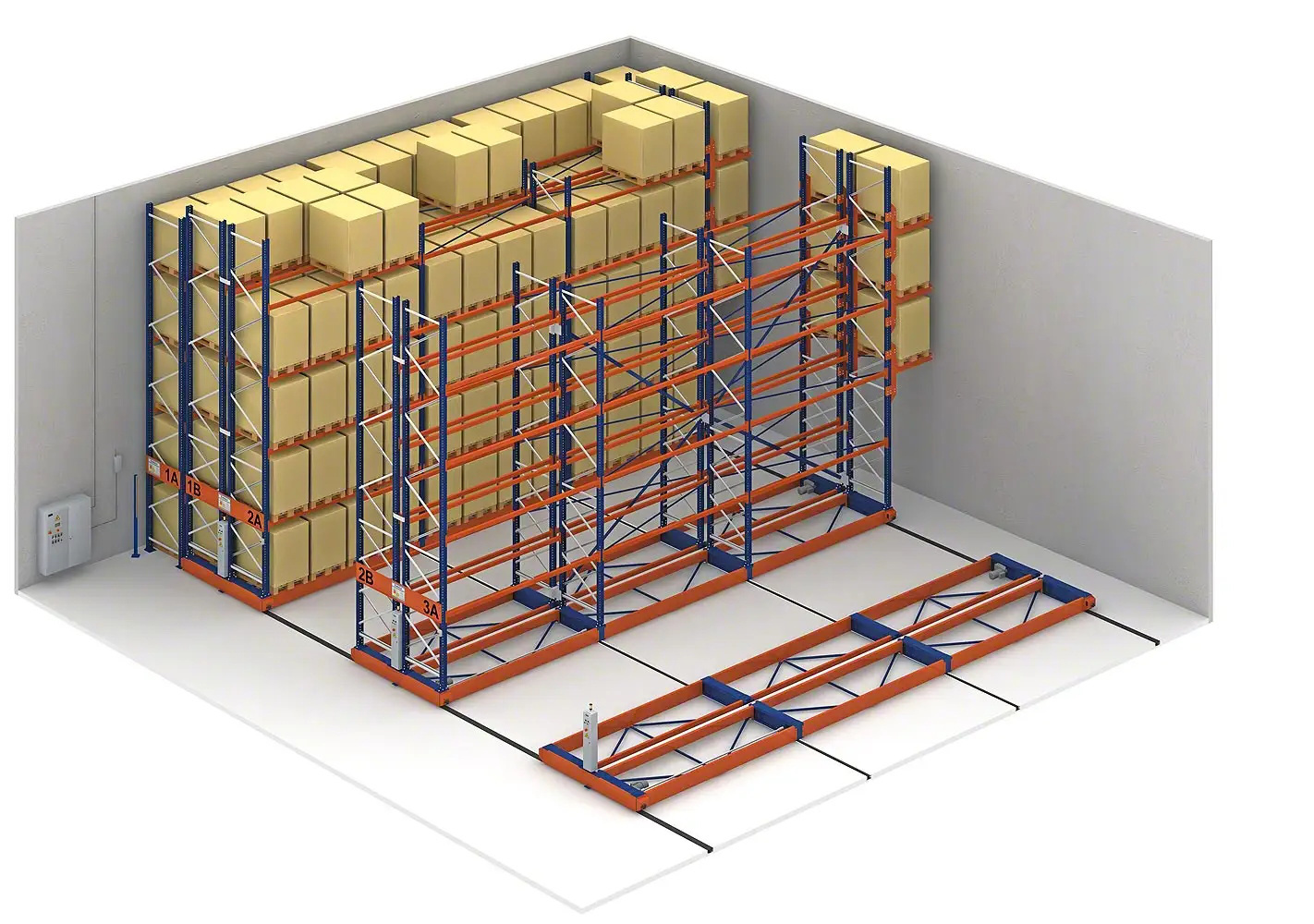

Maximized Space Utilization

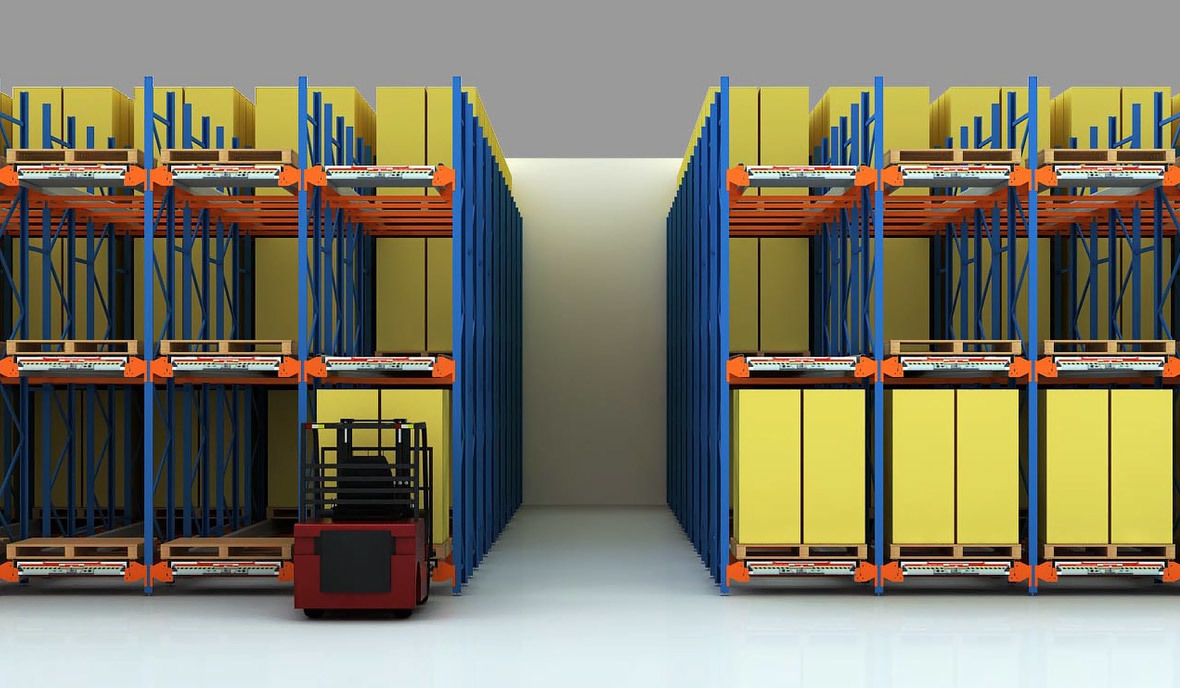

Only one operational aisle is needed, allowing other aisles to remain closed and thereby greatly increasing storage density.

Smooth & Safe Motion Control

Variable frequency drive ensures gentle acceleration/deceleration. Safety systems protect against collisions or misalignment.

Improved Storage Capacity

Compared to fixed shelving systems, mobile racks provide much more usable space within the same footprint.

Suitable for Low-Variety, High-Volume Items

Best suited for goods with fewer SKUs but large quantities, and lower frequency of inbound/outbound.

Direct Access Without FIFO Constraint

Each shelf line can be moved independently, allowing direct access to any storage row.

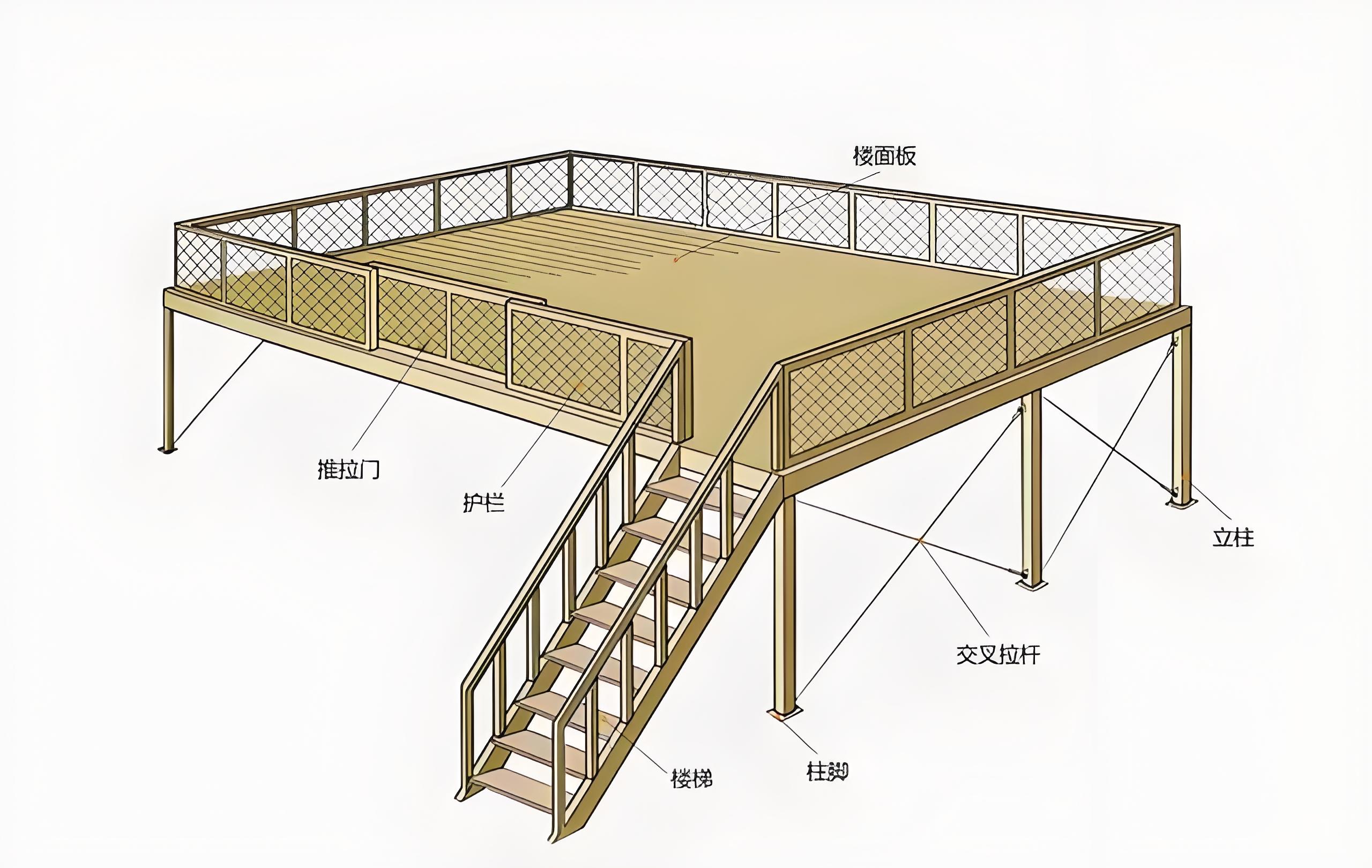

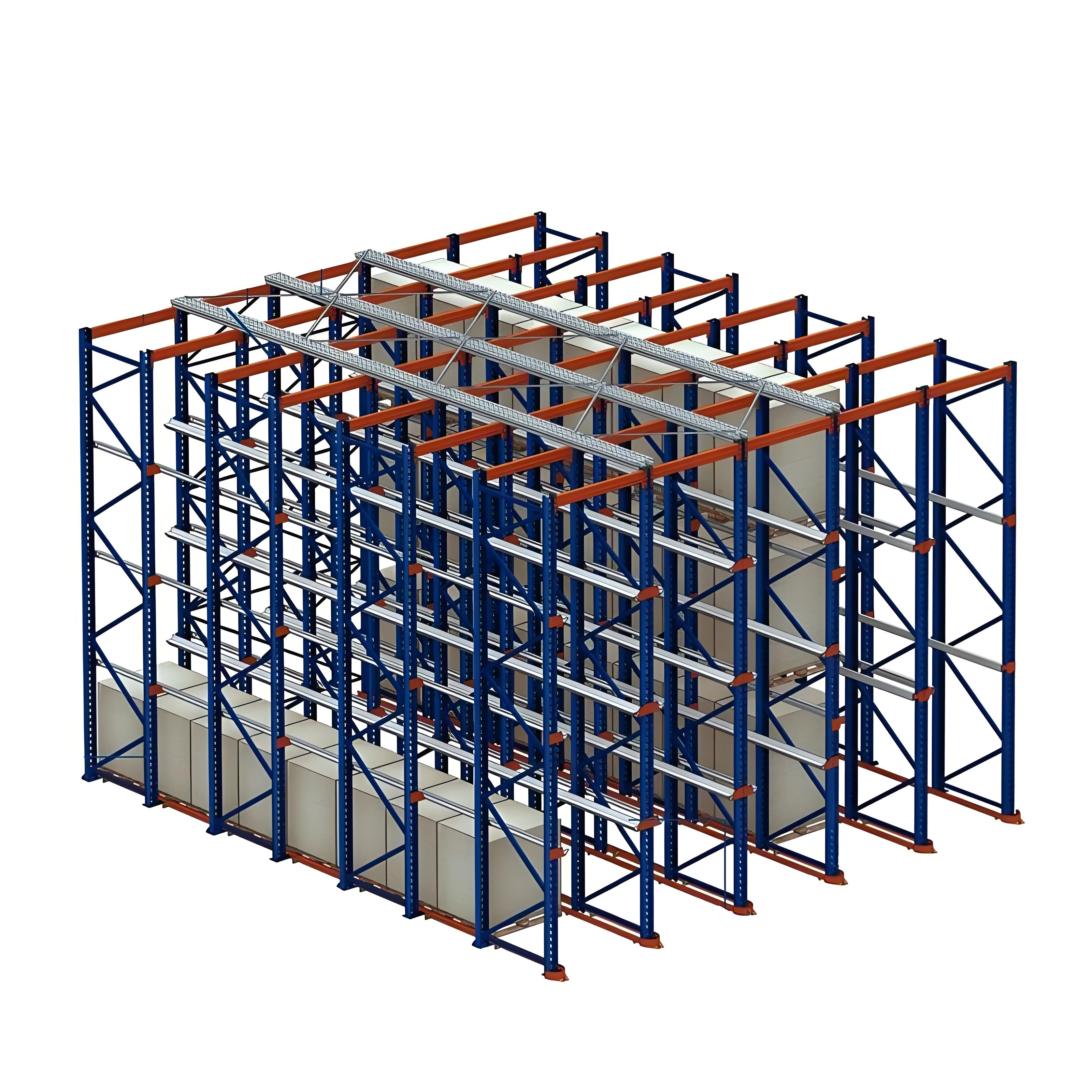

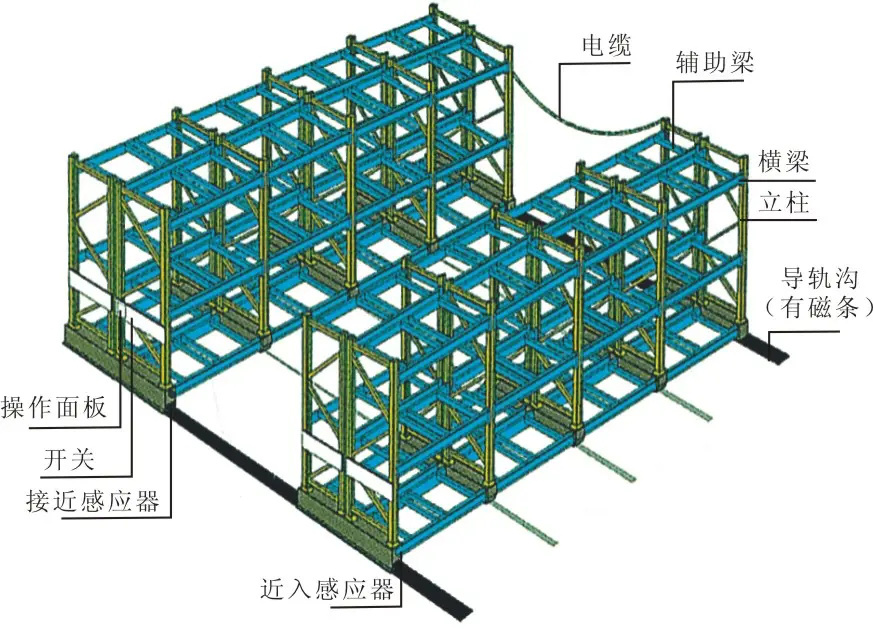

Structure & Components

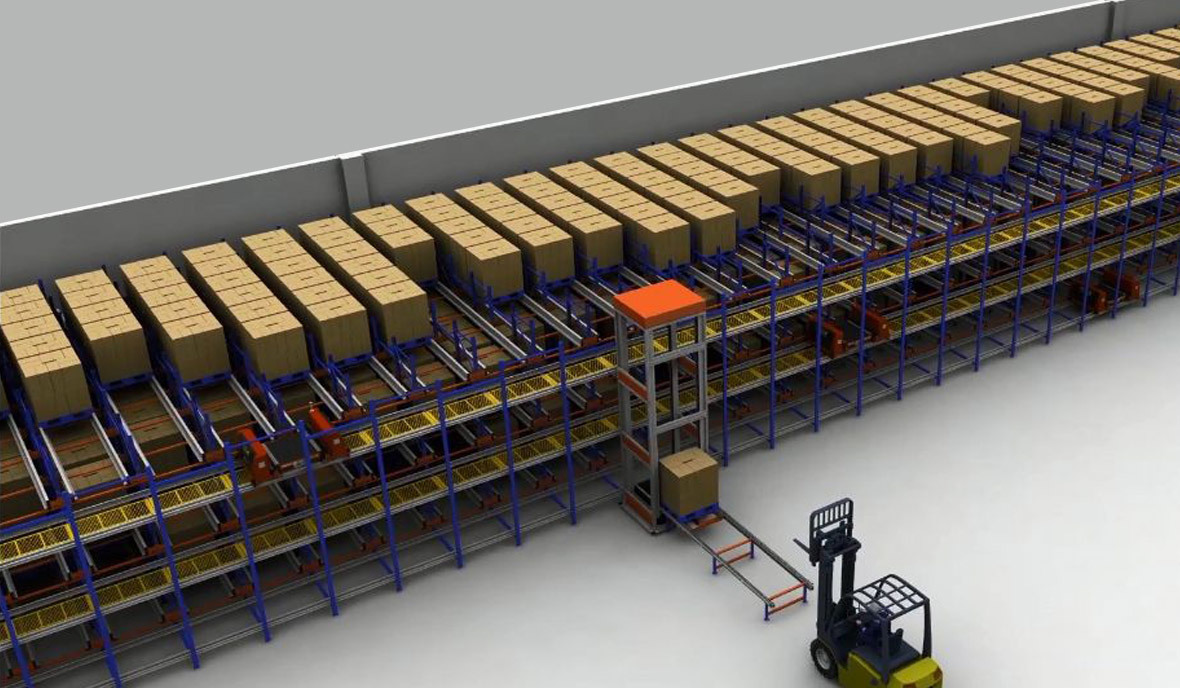

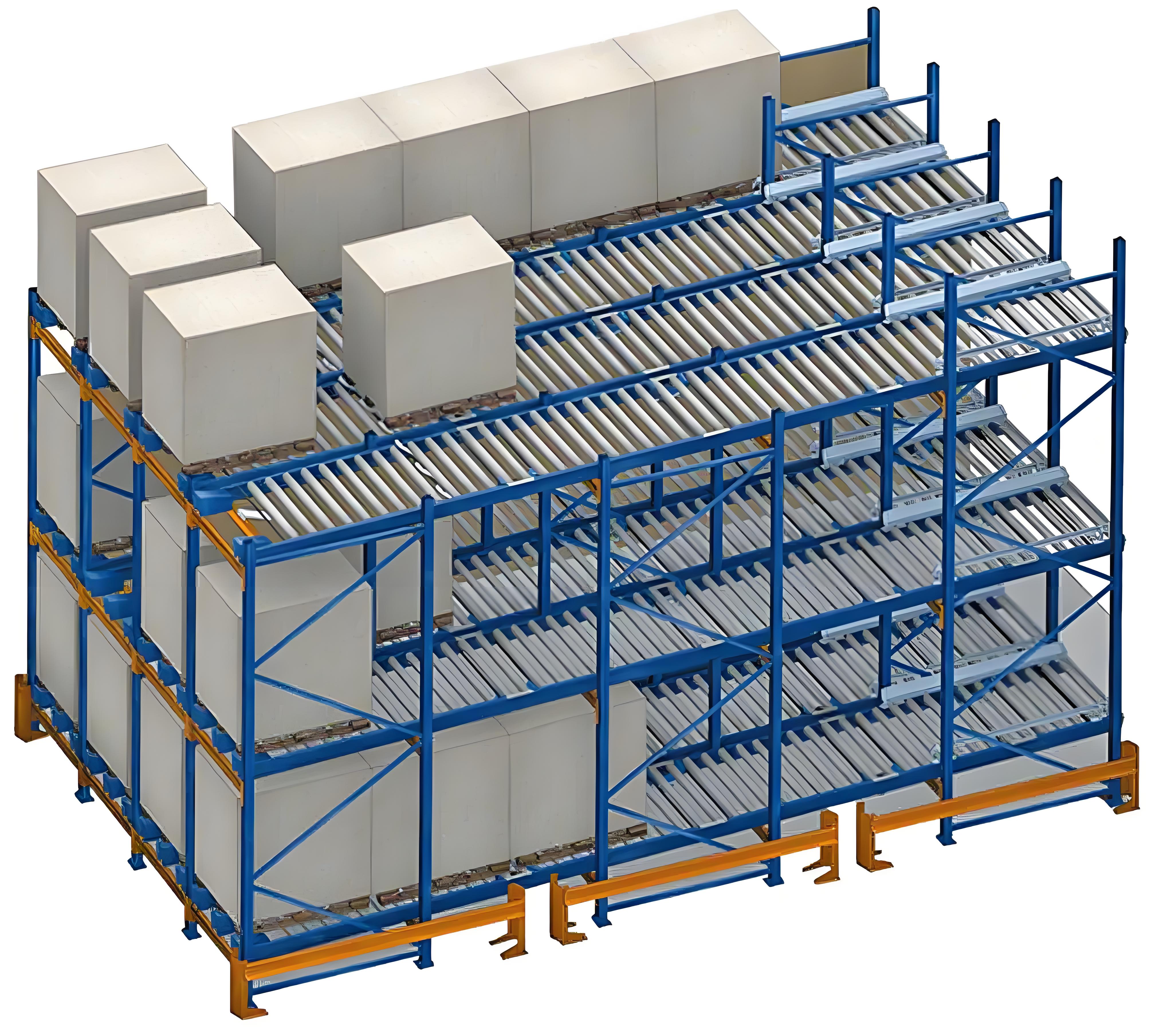

Mobile Bases (Carriages / Trolleys)

The motorized platforms on which shelving units are mounted.

Guide Rails

Precision rails installed on the floor to guide movement of mobile bases.

Shelving Units

Mounted on mobile bases—could be pallet racks, beam shelving, or cantilever shelving depending on your goods.

Drive System & Control Module

The motor, drive mechanism, and inverter control the movement.

Safety Devices

Collision sensors, limit switches, mechanical locks, buffer stops, anti-tip safeguards, emergency stop systems.

Applications & Use Cases

Mobile Racking systems are ideal in environments where space is at a premium and storage density is critical:

- Archive rooms, records & document storage

- Cold rooms / freezer storage (food, pharmaceuticals)

- Libraries, museums, galleries

- Media / film / microfilm storage

- Medical / pharmaceutical warehouses

- High value / sensitive items requiring compact storage

It’s especially beneficial when you have many items of the same model / SKU, large stock quantities, and less frequent movement between stock lines.

Design & Specification Options

| Parameter | Typical Range / Options |

|---|---|

| Drive Type | Electric motor + variable frequency control |

| Aisle Width | Only one access aisle required |

| Load per Shelf / Module | Depends on rack design |

| Movement Speed | 7.5 m-8 m/min |

| Safety Features | Collision detection, mechanical locks, emergency stop |

| Rail Type / Layout | Customized to flooring, rack footprint |

| Decking / Shelving Type | Beam shelf, pallet style, or other modular shelving systems |

We provide custom mobile racking warehouse layout design, structural calculation, and control system integration based on your warehouse geometry, ceiling height, and storage requirements.

Why Choose HEGERLS Mobile Racking?

- 30 years of experience in warehousing & smart logistics

- Patented technologies in automated and motorized logistics solutions

- Comprehensive service package: design, production, integration, installation & after-sales support

- High standards in quality and safety, conforming to international norms

- Customization and flexibility tailored to your storage needs

Contact & Next Steps

If you’re looking to dramatically increase your storage density without expanding your warehouse footprint, Mobile Racking is a powerful solution.

Get in touch with HEGERLS today for a layout consultation or a detailed quotation.

📞 Request a Quote / Layout Plan

📩 Email: hgls-wm@hbgysw.com

🌐 Website: www.warehouserack.cn

Key words:

Industrial Storage Systems

Heavy Duty Storage Racks

Mobile Racking Systems

Heavy Duty Shelving

Warehouse Racking Systems

Previous Page:

Next page:

Related Solutions

Shuttle + Forklift (AGV forklift) Intelligent Intensive Storage System and Solutions

Shuttle + stacker crane intelligent dense storage system and solution

Shuttle car & carrier + lift intelligent dense storage system and solution

Related Products

Product free consultation

HEGERLS has become a comprehensive, full-range, full-quality one-stop integrated warehousing and logistics service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Our staff will contact you within 24 hours (working days)

If you need other services, please call

Service Hotline:0311-87240955